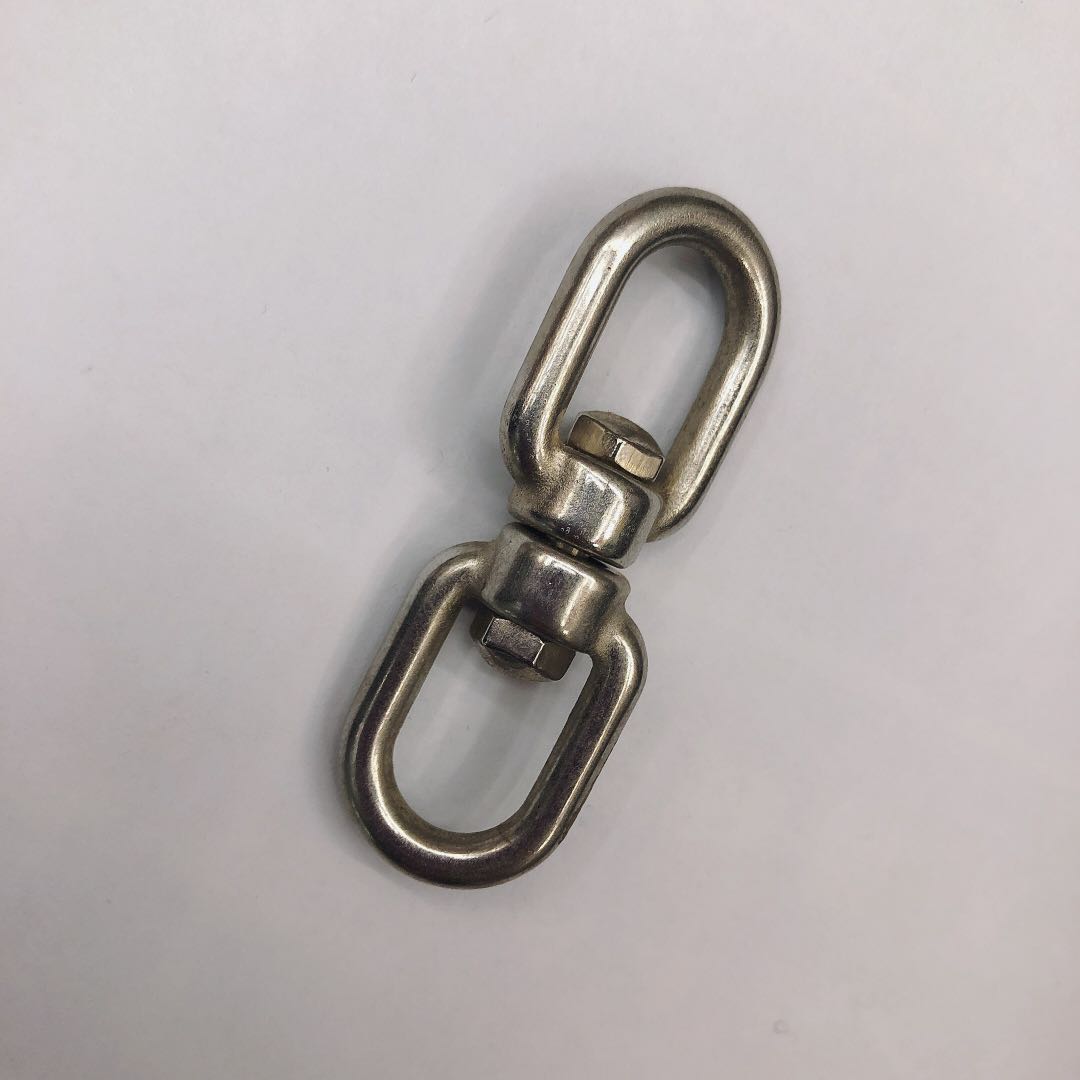

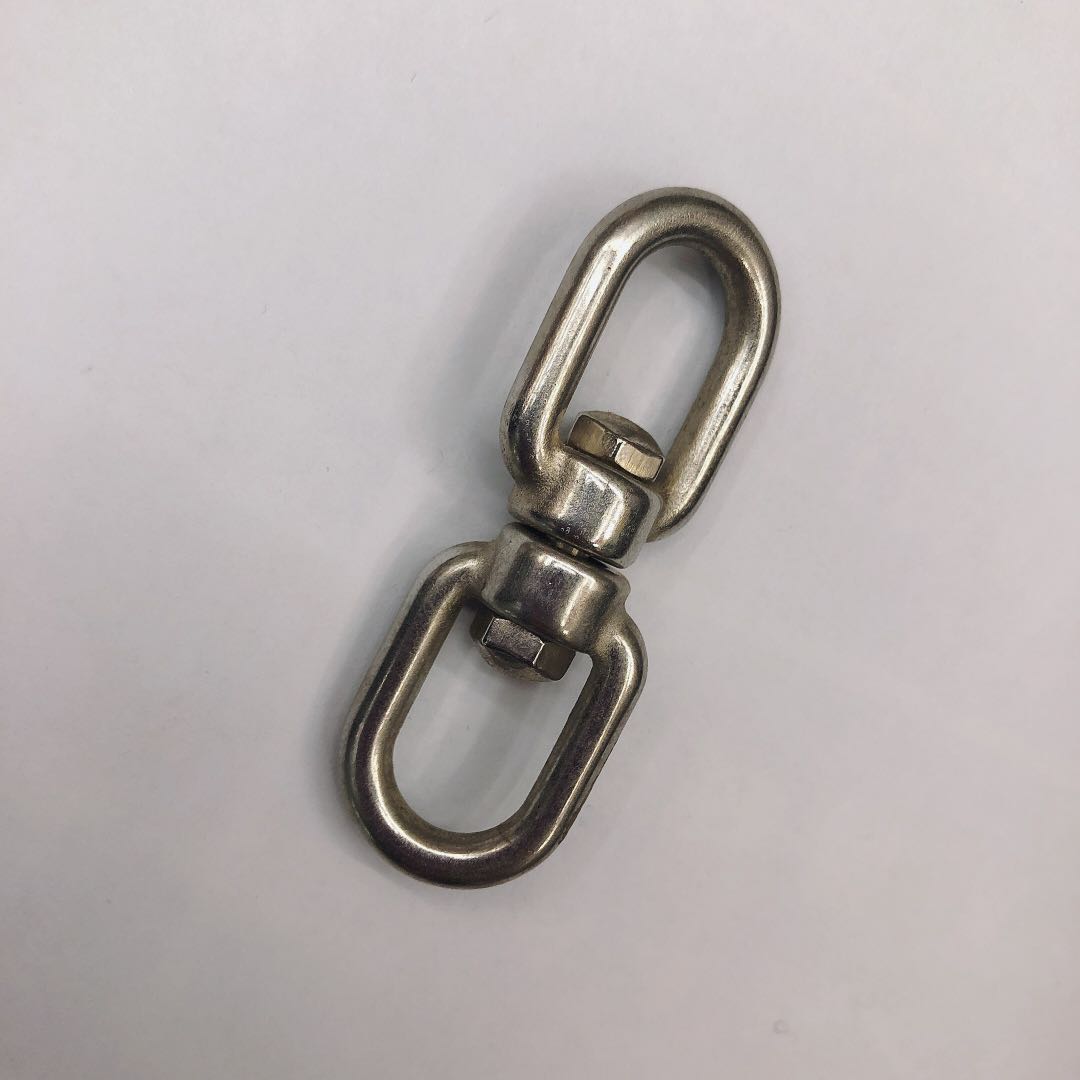

Rugged: Unique advantages of 304 stainless steel

In the industrial field, it is important to choose a material that can stand the test of time. This is why we have chosen to use 304 stainless steel for our rotating rings. Compared with other common metal materials, such as iron or aluminum alloy, 304 stainless steel has excellent corrosion resistance and rust resistance. This means that it can remain intact for a long time in extreme environments.

There is a solid scientific foundation behind this excellent performance. 304 stainless steel contains chromium and nickel, these elements give steel a strong antioxidant capacity. Even if exposed to humid air or contact with corrosive substances such as salt water, it will not be easily affected. Therefore, whether in offshore platforms, chemical plants or outdoor facilities, components made of 304 stainless steel always perform well.

All-round flexibility: 360-degree free rotation without dead angles

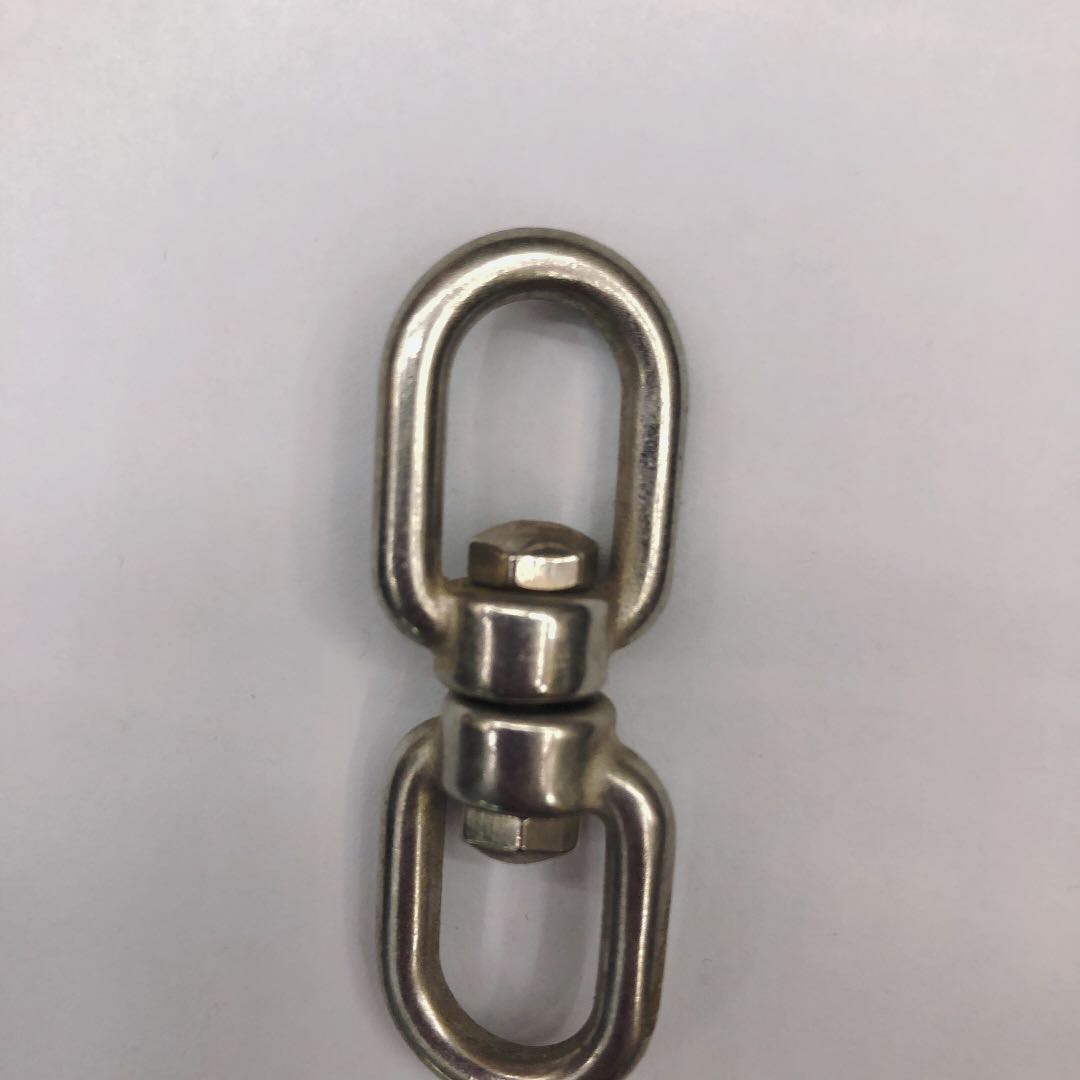

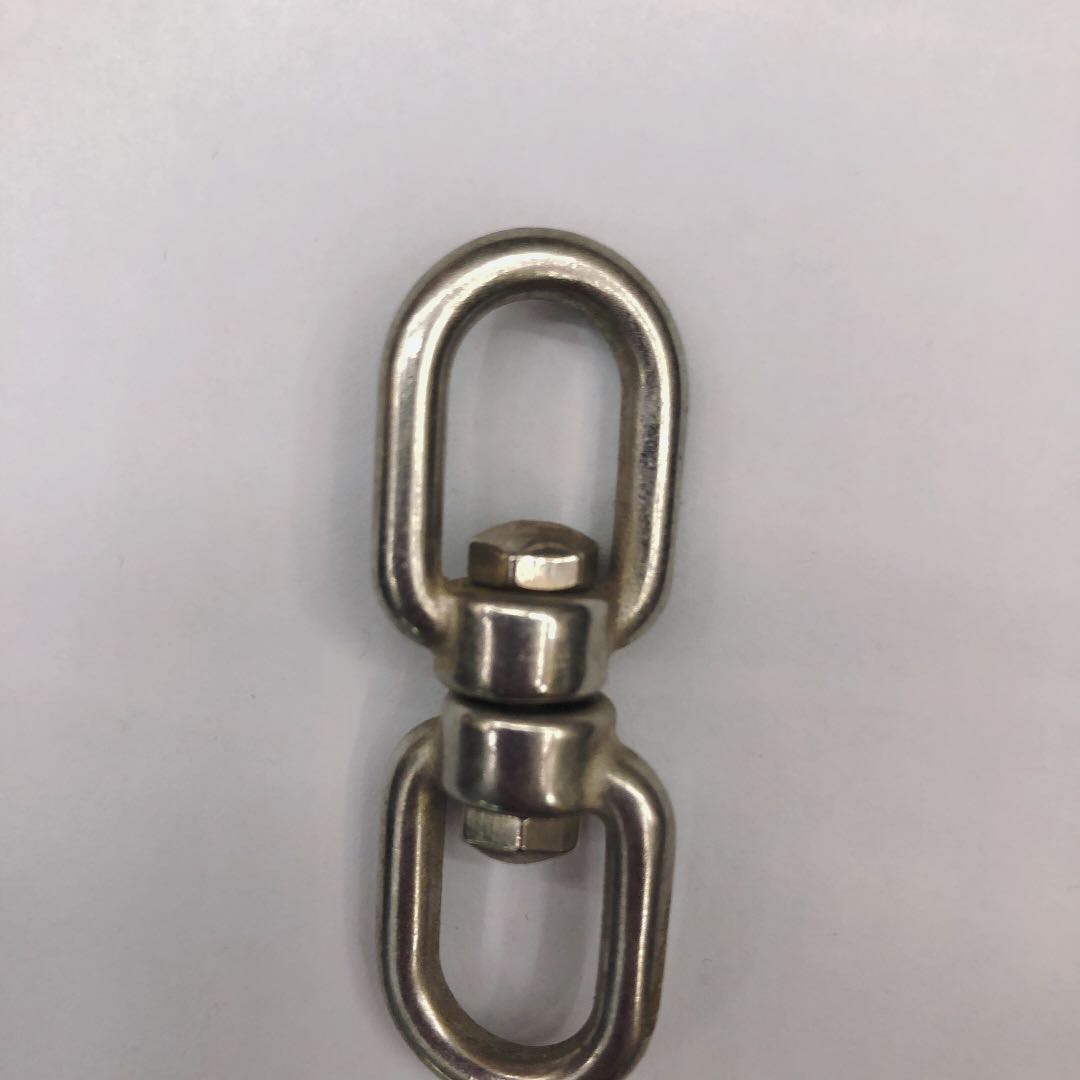

The biggest highlight of this universal rotating ring is its core function-equipped with a high-strength quick metal joint, which realizes a true 360-degree full-angle rotation. This technological innovation is not just as simple as it seems; in fact, it is the result of years of research and development. Engineers faced many challenges, such as how to ensure smooth rotation without loss of accuracy, how to prevent wear and tear, and finally found the ideal solution.

This design enables it to play an important role in a variety of application scenarios, such as the need for frequent movement of mechanical arm joints to complete precise operations; robot moving parts require high frequency of direction conversion and stability and reliability. Through experiments, it is proved that the product can fully meet the above harsh conditions and bring unprecedented convenient experience to customers.

Safe and reliable: long-lasting and stable connection guarantee

Safety is one of the primary considerations in our product development process. This universal rotating ring can not only withstand heavy load tasks, but also ensure that long-term operation will not loosen. This is supported by the professional test report issued by the authoritative organization, and the results show that all indicators have reached or even exceeded the industry standard level.

In addition to excellent quality, we also attach great importance to user feedback. Many customers reported that after using our products on their production lines, there has never been any accident, which greatly improves work efficiency and reduces maintenance costs. In addition, we offer industry-specific, customized service options to better meet the individual needs of different sectors.

Easy installation and maintenance: Simplify the operation process

Considering the convenience in practical applications, we fully listened to the opinions of end users at the beginning of the design. The whole system uses a simple and quick assembly method, even the first-time users can quickly grasp the essentials. In order to help everyone get started faster, we will break down the installation steps into a series of easy-to-understand text instructions, and cooperate with vivid photos to assist teaching.

At the same time, we also give detailed guidance on daily maintenance. Including regular check whether the fastening screws are loose, clean the surface oil dust and other tips. For possible problems, we have also prepared solutions to ensure that the equipment is always in the best condition.

Multi-field application example: witness excellent quality

Since its launch, this 304 stainless steel universal rotating ring has been widely used in various industries and has achieved remarkable results. In a typical manufacturing assembly line automation project, business owners mentioned that they were worried that the newly introduced technology would lead to more production line downtime, but in fact it was just the opposite. Thanks to our high-performance accessories, all mechanical equipment runs more smoothly and efficiently, and product quality is significantly improved.

Another successful case comes from a lifting device upgrade project on a large construction site. The project manager told us that the traditional parts used before often had problems resulting in delays in the construction period. After switching to the new universal rotating ring, there was no similar trouble. More importantly, construction workers generally believe that the new model is easier to control and more labor-saving than the old model.

Shopping Guide: Find the perfect accessory for your project

To enable consumers to make informed choices, we have compiled a detailed shopping guide. It covers many aspects, from the interpretation of basic parameters to the comparison of specifications and models, and strives to fully cover every key factor that may affect the purchase decision. Whether you are a novice in this field for the first time or an experienced professional, you can get useful information from it.

In addition, after-sales service is also a topic of concern to many people. Here we want to tell you that once you choose our products, it means to enjoy the whole worry-free service system. Whether it is pre-sales consultation to answer questions or after-sales technical support to solve problems, we will respond to customer needs as quickly as possible and wholeheartedly provide you with high-quality and considerate help.