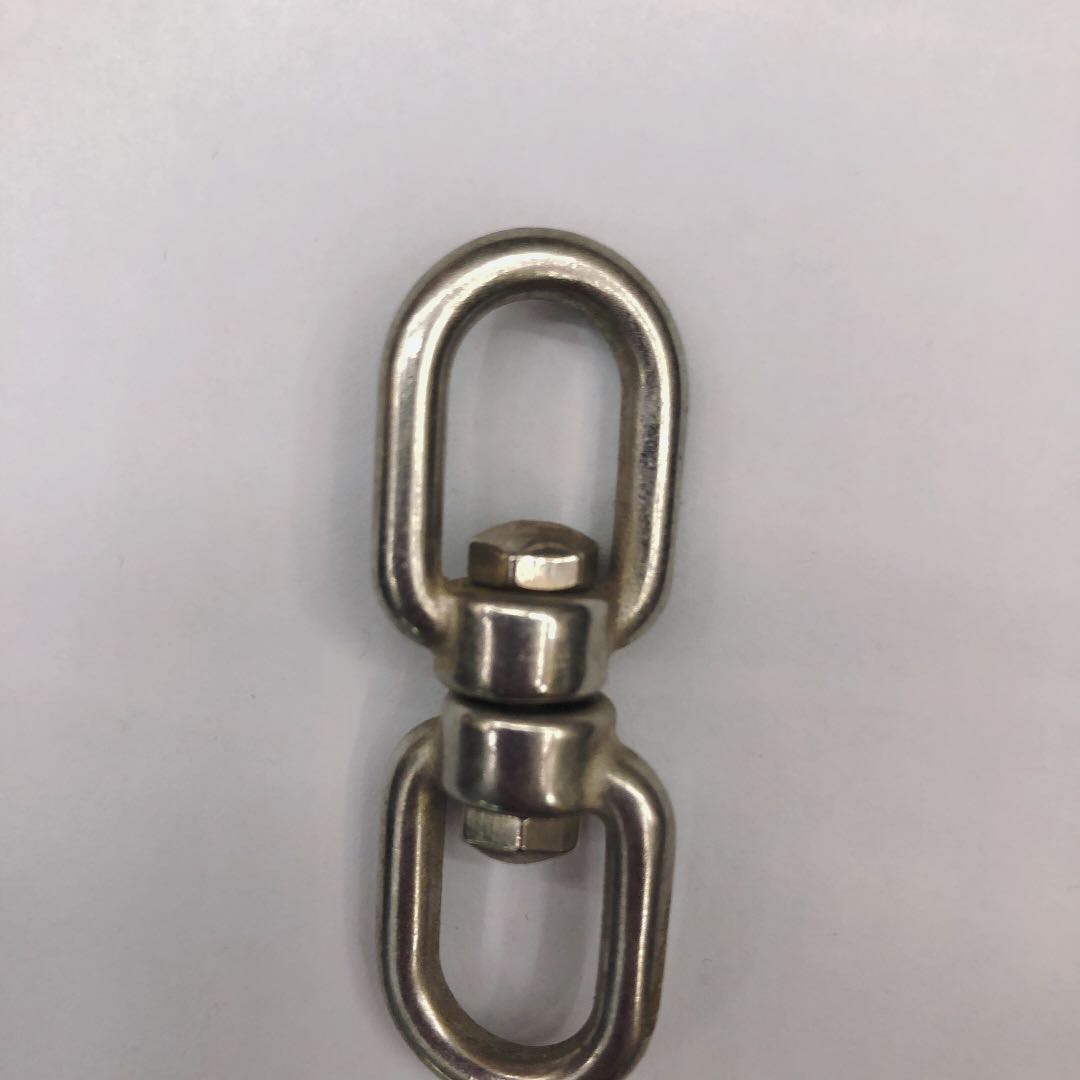

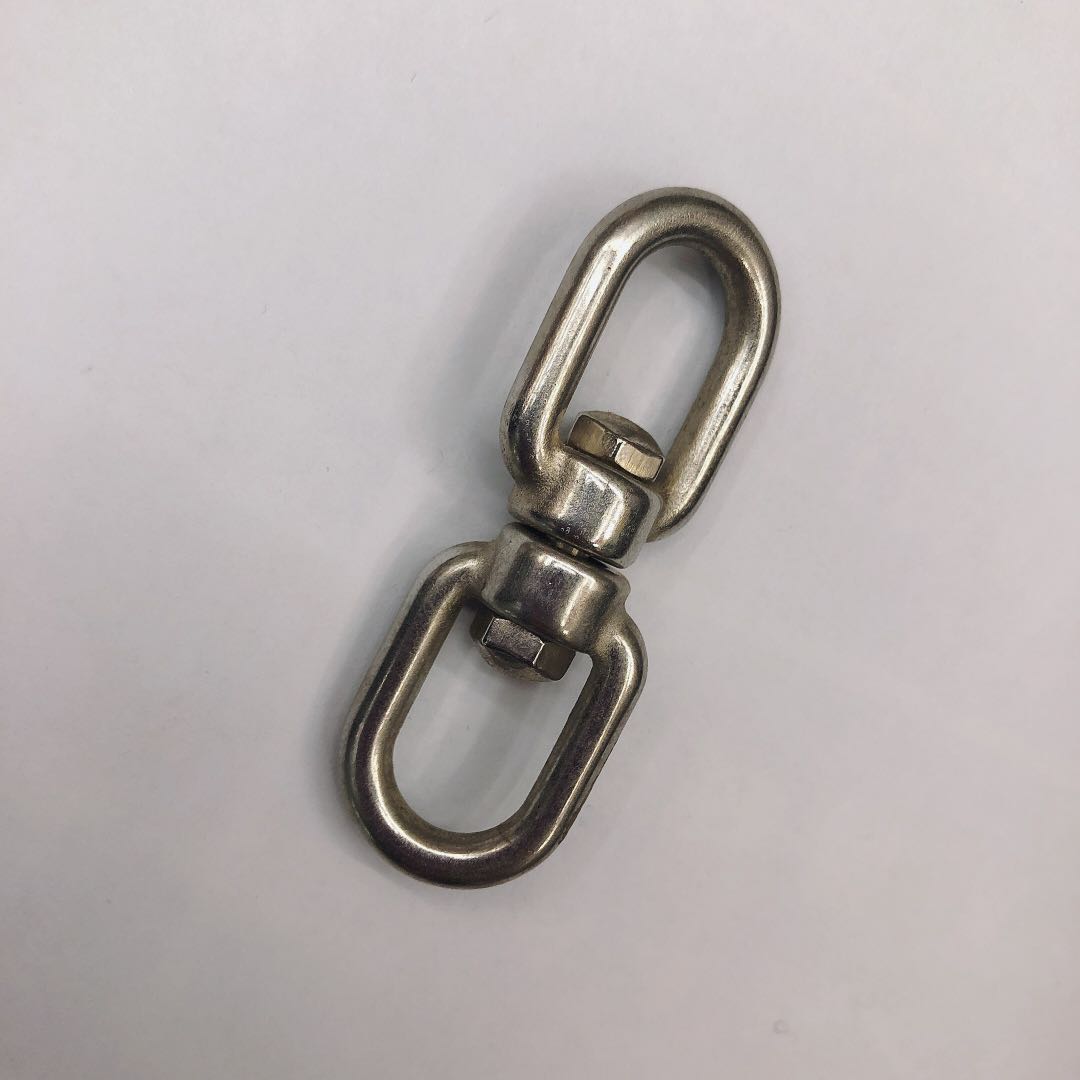

304 stainless steel universal rotating ring:

Ideal for M8 specification high-strength corrosion-resistant 360-degree joints

Excellent material: the extraordinary advantages of 304 stainless steel

The choice of materials is crucial when selecting engineering parts. For this universal rotating ring, the use of 304 stainless steel is undoubtedly a wise move. As a high-quality alloy steel widely used in aerospace, chemical and other high-end fields, 304 stainless steel is known for its excellent corrosion resistance and high mechanical strength.

Compared with ordinary carbon steel and other aluminum alloy products, 304 stainless steel can be stable and undeteriorated in a variety of harsh environments such as acid, alkali, salt spray, and is not susceptible to oxidation, which may cause problems such as surface rust and peeling. In addition, its good ductility allows manufacturers to easily process and shape, ensuring accurate and consistent dimensions of the finished product.

Precision design: the secret of all-round seamless connection

In order to achieve a true 360-degree free rotation without dead corners, designers have put a lot of effort into trial and error improvement. From the appearance point of view, the entire rotating mechanism has smooth and round lines; and after in-depth analysis of the internal structure, it will be found that each part is carefully polished and assembled together to form a compact whole.

Particularly worth mentioning is the bearing part, the use of high-precision ball with wear-resistant sleeve to reduce friction resistance, so that even after a long period of high-frequency torsion will not loosen Caton phenomenon. This not only improves the work efficiency and reduces the probability of failure, but also increases the service life and reduces the later maintenance cost.

Rugged: Power Source of M8 Threaded Interface

As a key part of connecting other components, the M8 specification threaded interface carries a vital mission. This standardized size is widely adopted by the industry because it not only has enough contact area to ensure stability and reliability, but also does not lead to excessive space occupation due to excessive volume.

Actual tests show that this type of joint can withstand pressures of up to several hundred Newtons and torque loads of tens of kilograms, and can still perform well under extreme conditions. For example, a large crane boom uses a product series with the same configuration, even in the face of severe tests such as wind, sun and rain, there is no problem.

Widely used: from factory floor to outdoor adventure

With the above advantages, this universal rotating ring quickly won the favor of the market and has been widely used in all walks of life. The flexible pipe adapter required for the automatic control system on the manufacturing production line is one of them; the seat belt buckle used for aerial work in the field of construction engineering is also inseparable from this kind of high-quality hardware support; even outdoor sports enthusiasts They will also carry a few spare parts with them, just in case they can come in handy in an emergency.

Regardless of the use scenario, this connector can provide the best solution for perfect matching and greatly facilitate the user's daily life or professional activities.

User Testimonial: Real Feedback Achievements Quality Assurance

Numerous loyal customers have given a high degree of affirmation and support, and their sincere evaluation is the most powerful brand endorsement. A senior engineer pointed out: "Since the replacement of this new model, I have never worried about the risk of aging and fracture." Another mechanic added: "The installation is convenient and saves a lot of time and energy." There are also technicians sighed with emotion: "Every maintenance is very smooth and there has never been any trouble."

These first-hand experience sharing from front-line workers fully proves the characteristics of excellent product quality and considerate service, which undoubtedly enhances the confidence of potential consumers.

Maintenance Tips: Tips to Extend Life

In order to make your investment more lasting and effective, please follow these simple suggestions:

First, complete the initial installation and commissioning procedures in accordance with the instructions in the manual, and ensure that all fastening screws are tightened in place and there is no sign of loosening. Secondly, clean up the internal and external dust and debris regularly to avoid accumulation and obstruction, which will interfere with the normal operation function. Finally, it is necessary to check whether there is abnormal wear in key positions in time. If problems are found, new parts should be replaced in time to prevent further damage and expansion.

Taking the above preventive measures can not only greatly reduce the possibility of accidents, but also significantly improve the overall operating efficiency of the equipment and extend the service life.