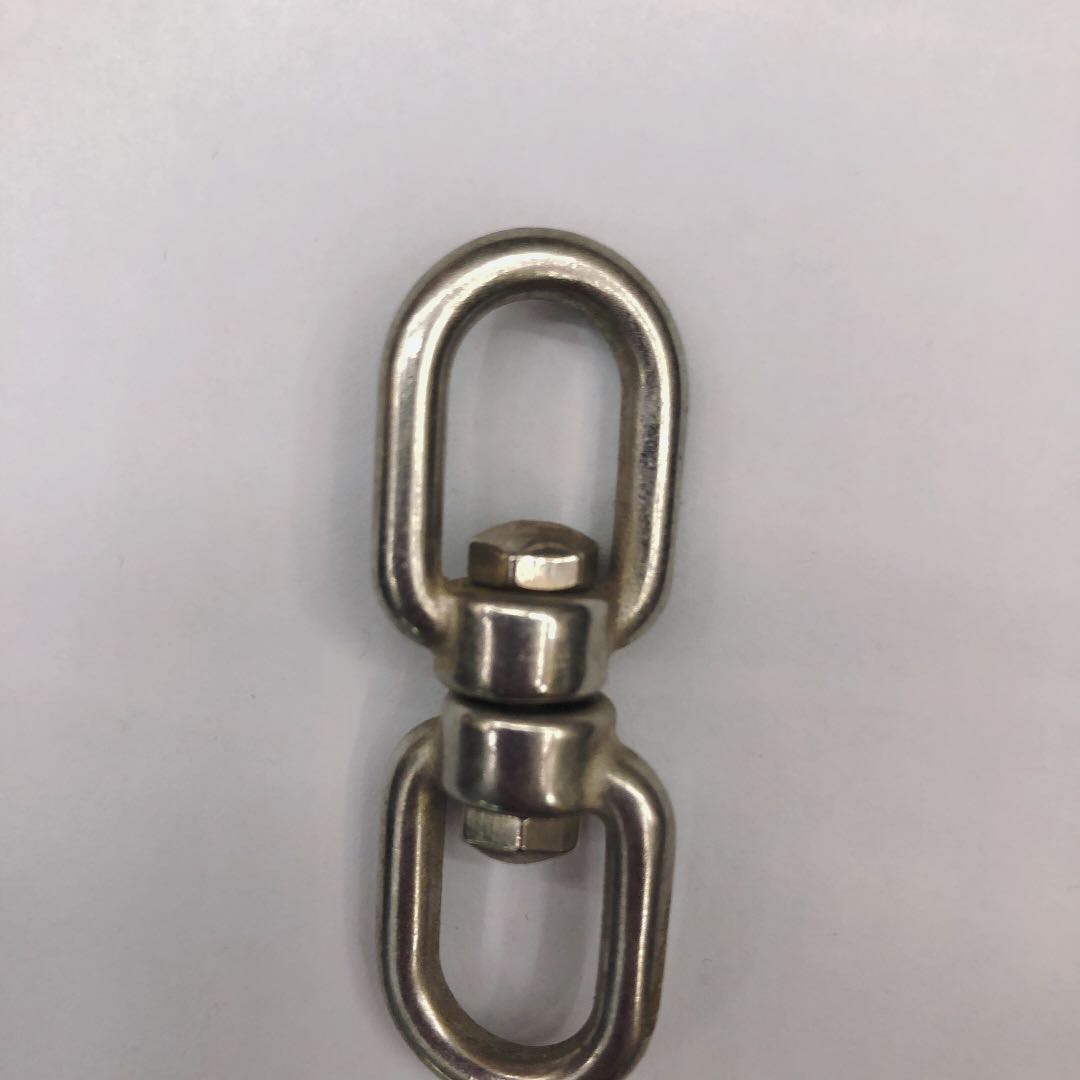

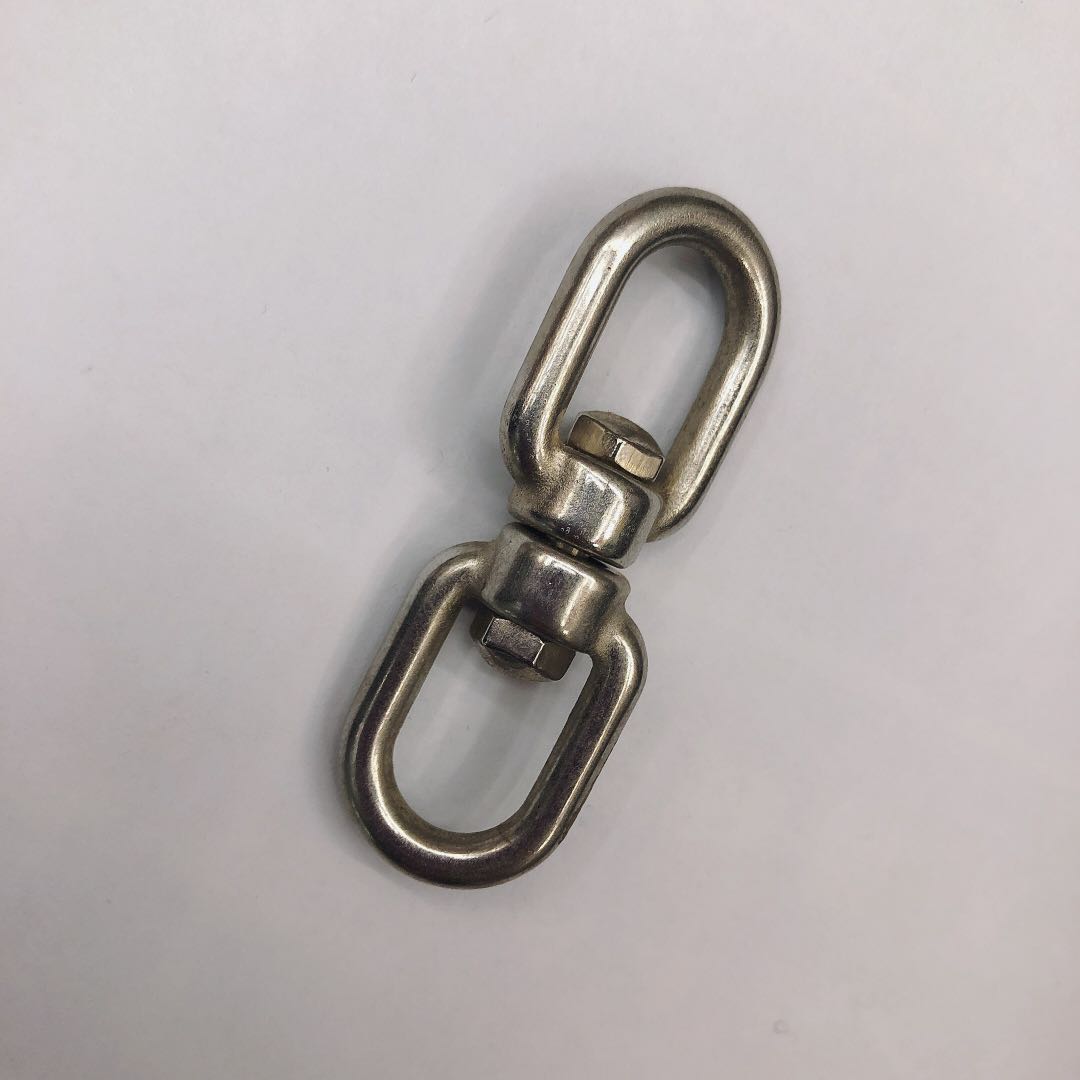

Explore the powerful functions of 304 stainless steel universal rotating ring

Learn more about the 304 stainless steel swivel ring, a high-performance accessory designed for a wide range of applications. It not only has excellent corrosion resistance and rust resistance, but also can withstand high-strength pressure without deformation. This small part plays an indispensable role in many industries.

Its core advantage lies in the use of high-grade 304 stainless steel, which is widely praised worldwide for its excellent physical properties. Through the advanced production process, the surface of the product is smooth and fine and evenly distributed with a layer of protective film, effectively prevent the invasion of harmful factors from the outside world. In addition, rigorous testing and certification shows that good working conditions can be maintained even under long-term exposure to salt spray test conditions.

There are also many impressive examples in practical applications. For example, in marine engineering projects, due to the fact that seawater is rich in chloride ions, it is easy to cause serious corrosion of ordinary steel products, and this universal rotating ring can easily cope with this challenge by virtue of its excellent characteristics. Similarly, it can also be seen in the complex piping system inside the chemical plant, providing a solid support for key parts.

All-round rotation: the perfect combination of flexibility and stability

Discuss one of the biggest highlights of the product-the ability to rotate in all directions in 360 degrees. Whether it is the application of the mechanical arm joint or the flexible adjustment of the solar panel bracket, this feature can significantly improve work efficiency and reduce maintenance costs.

The key to this technology lies in the special bearing design, which uses a high-precision ball structure to achieve a smooth and unimpeded motion trajectory. Each contact surface is finely ground and coated with a lubricant to reduce the coefficient of friction. In this way, it can not only prolong the service life but also feel excellent in operation. In contrast, most of the competitive brands on the market can only swing within a limited angle or have problems such as Caton, which is obviously difficult to match our level.

In addition, the engineers also fully considered the actual needs of users in the early stages of development. The high-frequency reciprocating action under certain conditions is optimized and improved to ensure that each rotation can be accurately in place without deviation. Therefore, whether you are a professional engaged in the management of automated production lines or a technician responsible for the operation and maintenance of photovoltaic power plants, you will benefit a lot.

Responding to extreme environmental challenges: the secret weapon of corrosion resistance

Analyze why 304 stainless steel can maintain long-term performance in harsh environments. Through the understanding of material science, explain the advantages of the internal structure of this steel and the importance of the surface treatment process. Examples are given to illustrate the successful application of the material in many industries around the world, including high-demand fields such as marine engineering and chemical plant pipeline systems. Finally, it is concluded that the reason for choosing this universal rotating ring is that it can effectively resist the erosion of various chemical substances and is easy to clean and maintain.

From a microscopic point of view, 304 steel contains a high proportion of chromium-nickel alloy elements, and these components interact to form a dense and firm chromium oxide film covering the entire surface. This is like putting an invisible armor on the whole piece of metal as a barrier. It is also worth noting that we have also used a series of professional means to carry out deep processing, such as pickling passivation treatment to remove impurities and enhance corrosion resistance. Electroplating coating reinforcement gives stronger wear resistance and so on.

In real life, there are many successful examples to learn from. For example, offshore oil drilling platforms are often faced with the test of wind and waves, sun and rain, and regular iron components are easy to rust and rot, causing potential safety hazards. However, there is no need to worry about these problems when the new model is replaced. In addition, pharmaceutical workshops are often exposed to a large amount of strong alkali and weak acid solution. If the container interface is not tightly sealed, it will leak and pollute the quality of drugs. At this time, we need to use the high-quality universal rotating ring we produce to ensure safety.

M8 interface: the best partner to simplify the installation process

Introduce the significance of M8 standard thread interface design and its convenience. The focus is on how the quick connect mechanism significantly reduces assembly time and labor costs. At the same time, some auxiliary tools (such as torque wrench) can ensure the correct tightening force to avoid excessive damage to the parts. In addition, the role of pre-installed gaskets and other seals will be mentioned to ensure that the connection parts are waterproof and airtight. On the whole, this part aims to send a message to potential buyers that using our products will make your project more efficient and smooth.

The first thing I have to say is the value of standardization. The standardized size specifications enable any technician to quickly identify and match the corresponding model components to complete the assembly task. It is no longer necessary to spend too much energy to find suitable alternatives, thus improving the efficiency of on-site construction and saving valuable time and resources. More importantly, the supporting provision of special sleeves and screwdrivers and other instruments can help users accurately apply force to achieve the best results.

The second is security. In order to avoid excessive force