Explore the importance of multifunctional connectors and their impact on modern industry

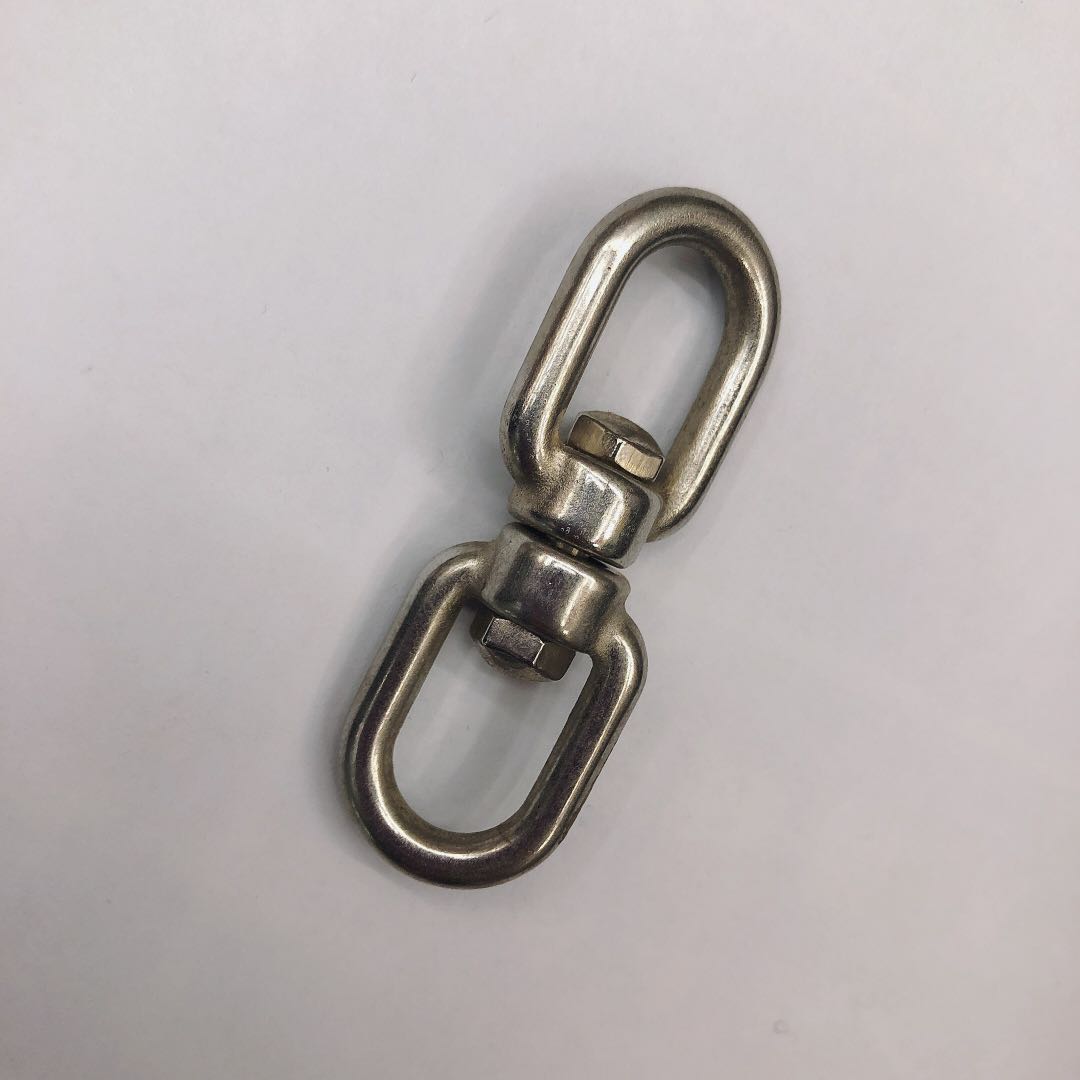

With the development of technology, connectors have become an indispensable part of many industries. An excellent connector can not only improve efficiency, but also ensure safety and stability. Especially in the field of machinery manufacturing, construction and other fields, a part that can withstand high pressure environment and flexibly adjust the direction is particularly important.

Learn more about the advantages of 304 stainless steel and why it is the best choice

As one of the globally recognized high-performance alloys, 304 stainless steel is known for its excellent corrosion resistance and mechanical strength. Whether in humid air or chemical solution contact conditions, can maintain the original state for a long time without being damaged by erosion. Therefore, products made of this material must have long-term durability and reliability.

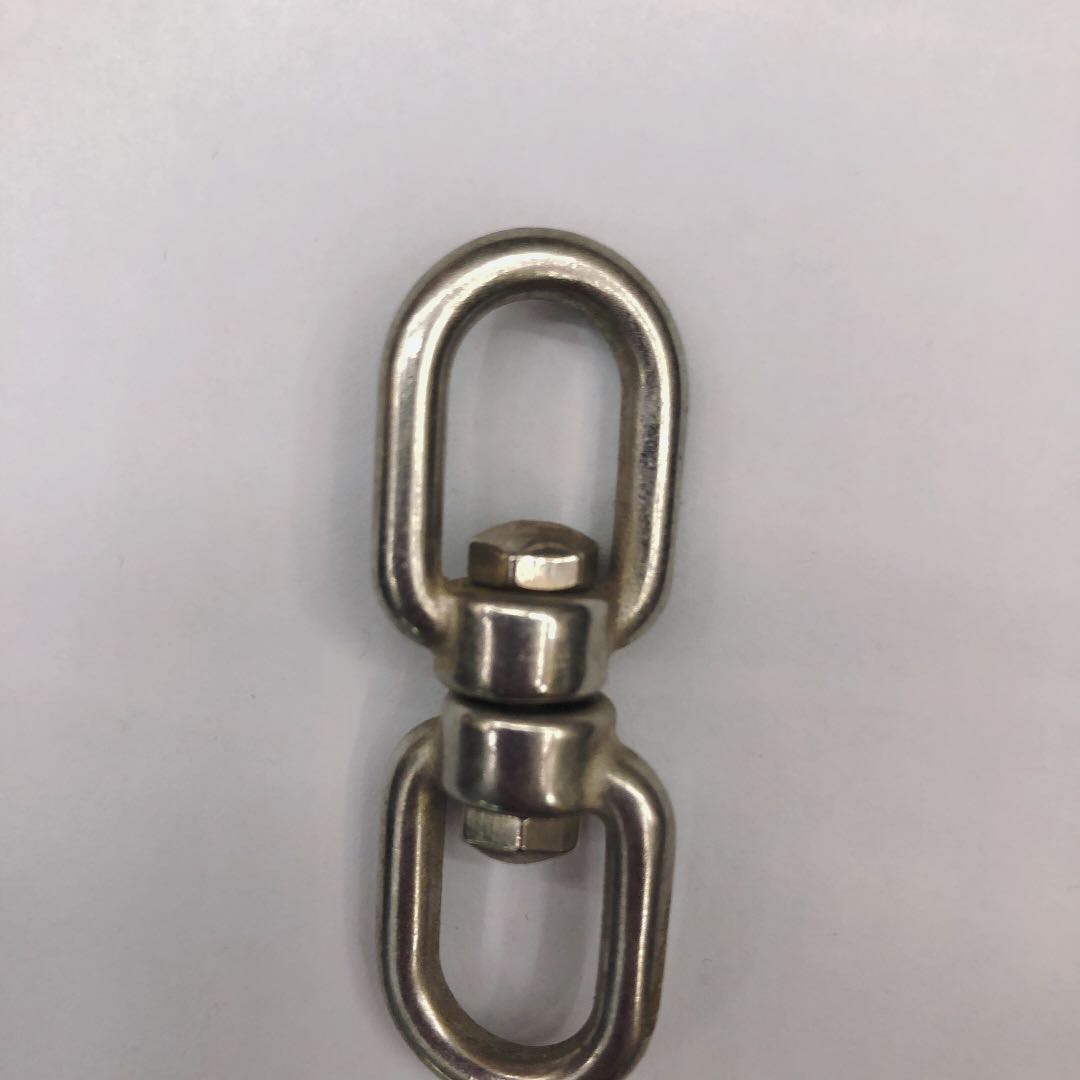

Revealing the scientific and technological principles behind 360-degree full-angle rotation design

The traditional fixed connection method is often limited by a single orientation and cannot change the position relationship at will, resulting in inconvenience in use or even unable to complete the task requirements. What we are introducing to you today is a breakthrough solution-a new generation of component structure that supports arbitrary orientation adjustment and always maintains close bite and transmits torque force without deformation and falling off. the so-called "ball bearing ball groove" combination application mechanism principle is simply to add a group of precision machined steel balls arranged in a circular distribution between two relatively moving parts to form rolling friction instead of sliding friction and greatly reduce the degree of wear at the same time. Also make the operation more portable.

From rust to corrosion: analyze the reason why this rotary joint is durable

In addition to the innovation in the external form, there are also many innovations at the micro level. For example, the surface treatment process adopts advanced passivation technology and the double protection measures of electroplating coating to further enhance the ability to resist external aggression, even if it is in harsh conditions for a long time, it can perform its duties and missions safely. In addition, the strict quality inspection process ensures that every single item meets the expected standard before leaving the factory, so users can safely purchase and use it boldly.

How to make full use of M8 standardized interface to achieve maximum adaptation capability

M8 specification is one of the international common thread sizes, which is widely used in many fields. this means that as long as you need to use screw holes with a diameter of about φ Φ8mm anywhere in your existing system, you can seamlessly connect them for expansion, transformation or replacement of old models. This not only simplifies the purchase decision-making process but also reduces the inventory backlog and improves overall operational efficiency.

Real Case Study: Excellent Performance of the Product in Various Scenarios

many enterprises have verified the powerful functions of such devices in actual projects. for example, a large wind farm has deployed it to the top of the tower for fixing the camera pan-tilt bracket to realize all-weather monitoring picture transmission. the phenomenon of loosening and shifting caused by wind, rain and sun will no longer occur. In addition, a large number of similar components have been introduced into the assembly line of the automobile manufacturing industry to help the smooth completion of assembly line operations, greatly improve production efficiency and reduce costs.

Maintenance Guide: Tips for Extending the Life of Rotary Joints

although the above-mentioned advantages are reliable enough, in order to prolong the service life as much as possible, some details need to be paid attention to, such as regular cleaning of dust and dirt to avoid excessive accumulation and affecting normal operation. Apply lubricating oil in due course to reduce the frequency of dryness and stagnation. It is necessary to be cautious to avoid problems such as permanent deformation and damage caused by overload operation exceeding the rated parameter range.