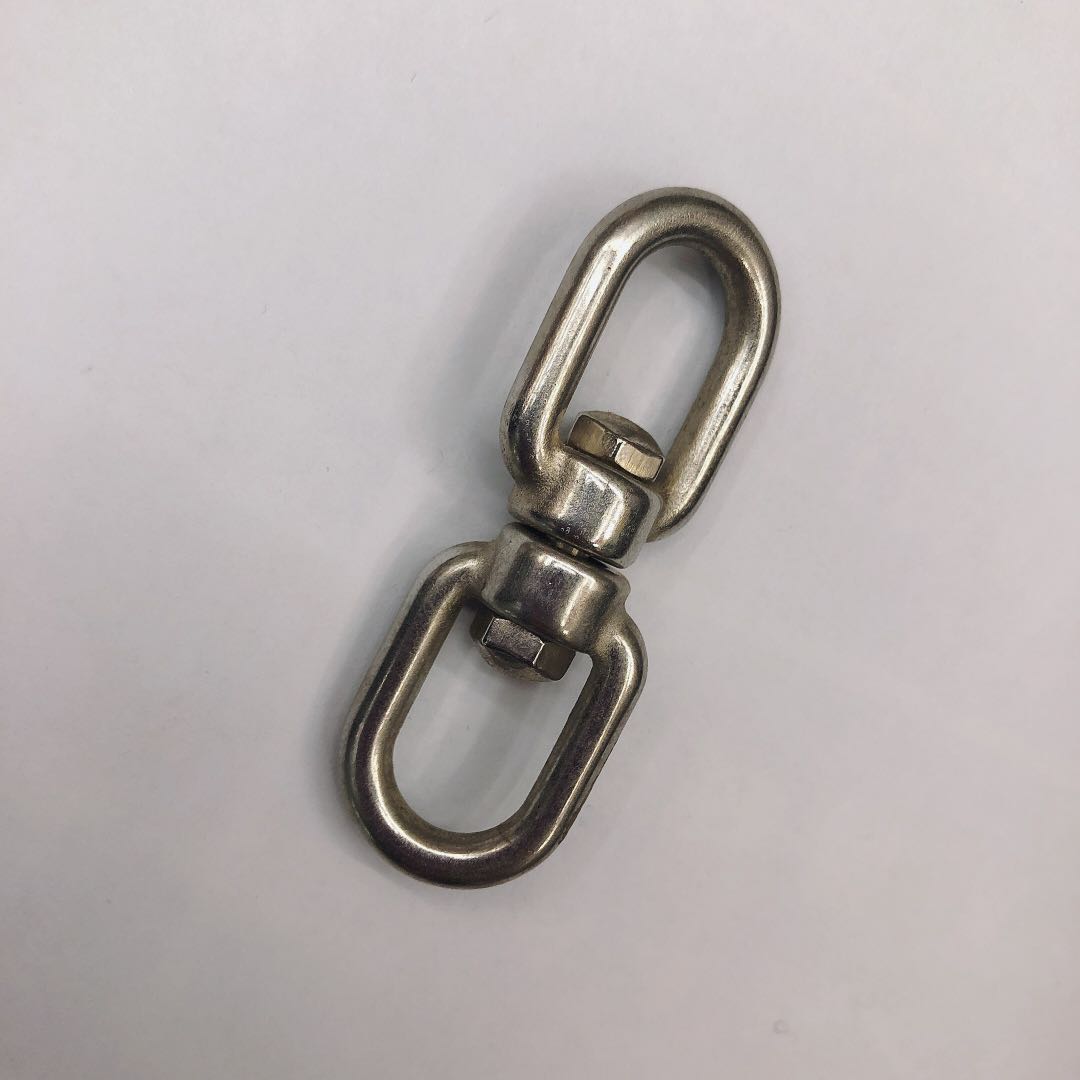

The cornerstone of excellent quality: in-depth analysis of the advantages of 304 stainless steel

Among many engineering materials, 304 stainless steel stands out due to its unique physical properties and superior weather resistance, and has become one of the first choices for industrial-grade products. This alloy steel can not only resist the salt spray, acid and alkali erosion and other challenges brought by the harsh environment, but also maintain stable mechanical properties. Compared with other commonly used carbon structural steels or ordinary low-alloy high-strength steels, it has higher strength and better ductility, making it the best choice for manufacturing high-end universal rotating rings.

When faced with complex operating conditions, such as offshore platform construction, chemical production equipment and other fields, only special steel such as 304 can ensure long-term safe operation without worrying about functional failure caused by external factors. In addition, there are significant advantages in terms of daily maintenance costs-due to the excellent corrosion protection characteristics, the frequency of regular painting protection work is reduced, thereby reducing the total cost of ownership.

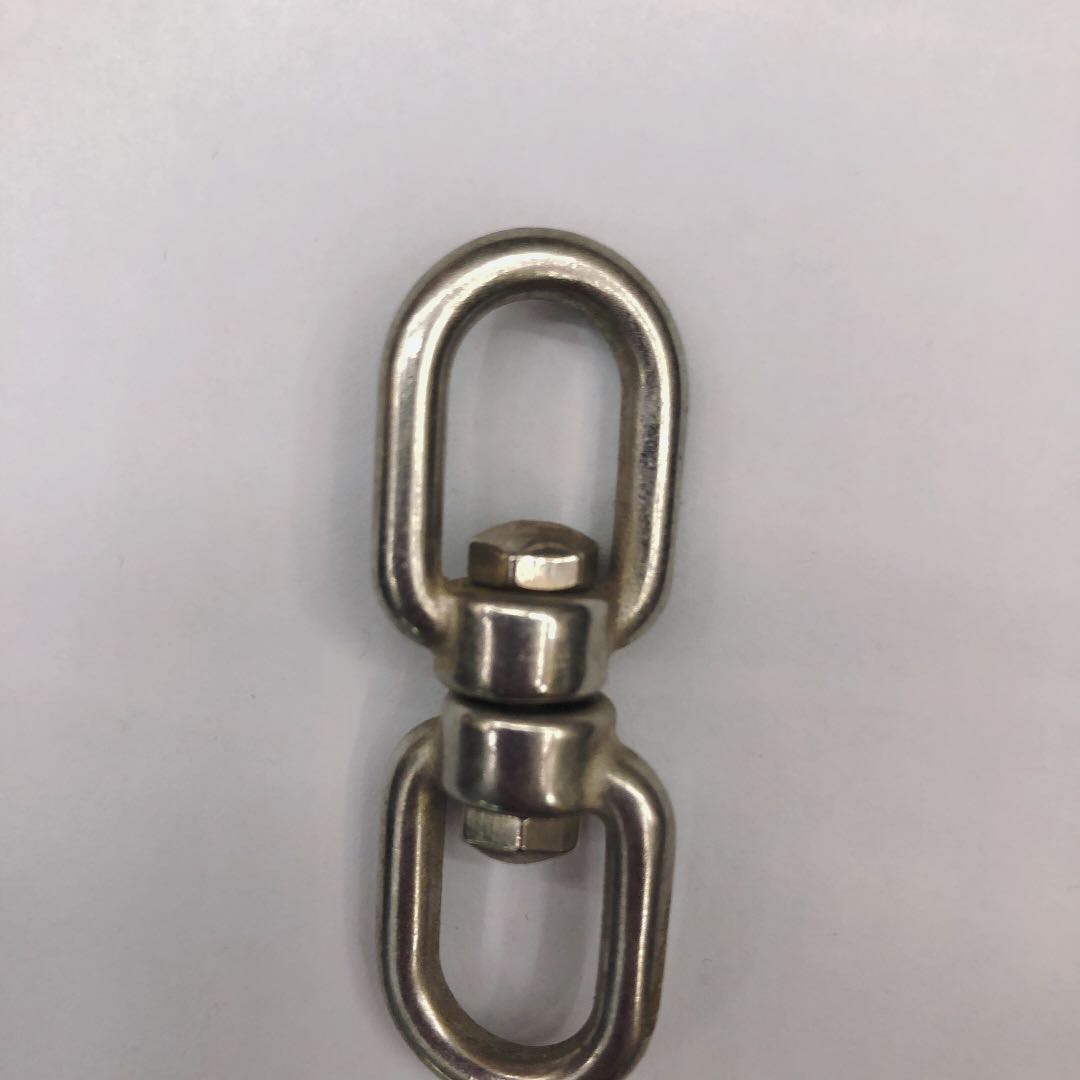

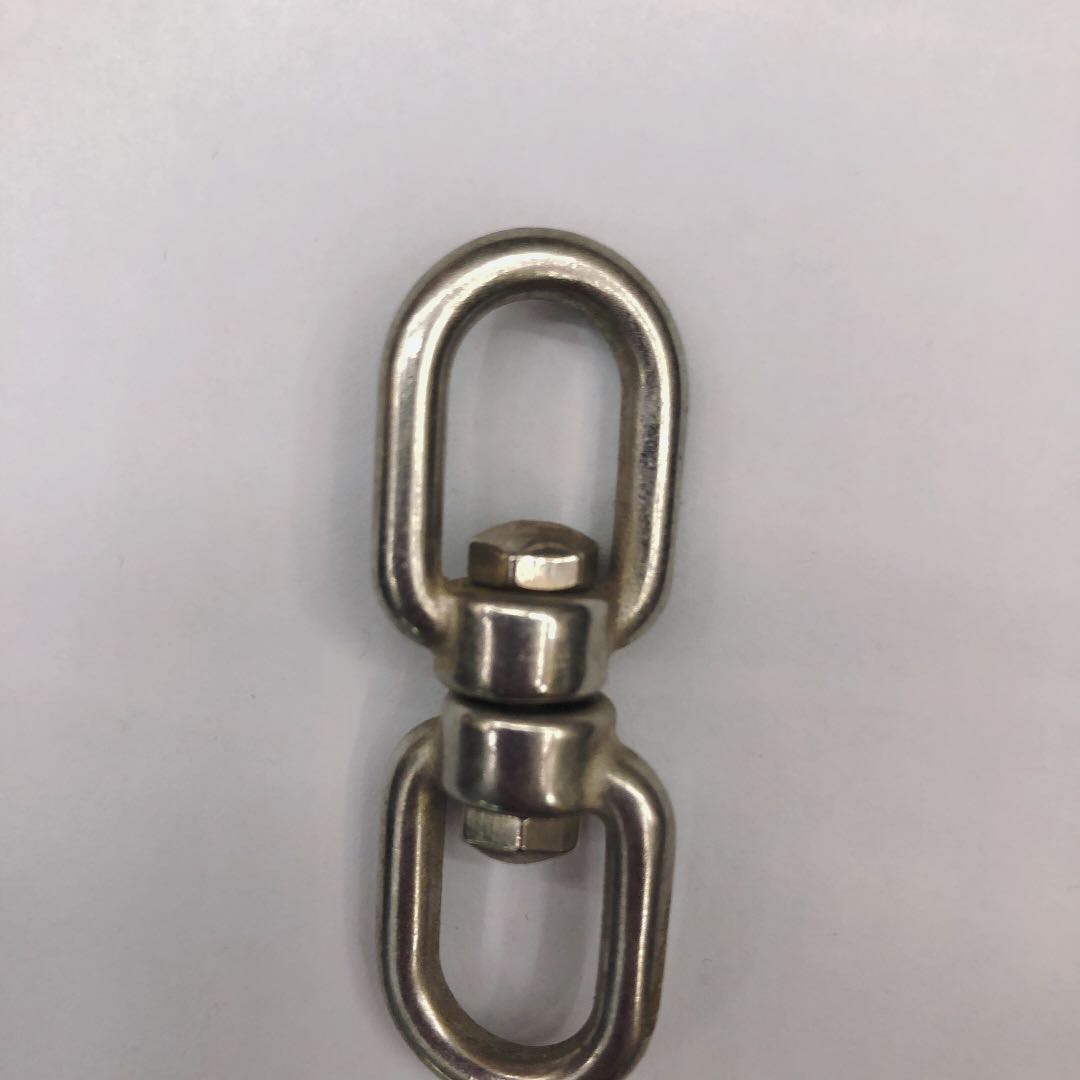

Flexible core component: revealing the secret of 360-degree full-angle rotation

The secret to this gimbal ring's ability to rotate smoothly and unimpeded in any direction is its well-designed internal bearing system. This key component uses advanced precision machining technology to create an extremely smooth and flat contact interface, ensuring that every movement is as smooth as silk. Whether it is in frequent operation day after day, or encounter long-term continuous operation, this exquisite mechanism has always performed well and provided reliable support.

By optimizing the friction coefficient and introducing an efficient self-lubricating mechanism, we have achieved effective suppression of wear. This means that even after many years of uninterrupted work, your equipment will still run as smoothly and efficiently as the first day. This is especially important for applications that rely on precise position adjustment, such as the fixation of the joint parts of the robot arm on an automated assembly line, or the firm connection between the rocker arm holder during film and television shooting.

Convenient and efficient assembly experience: Design concept for quick disassembly and installation

In order to make the user's on-site debugging easier and faster, our R & D team has specially developed a set of one-button locking device concepts. This intelligent solution allows users to quickly complete the assembly process of the entire assembly with the push of a button, with almost no additional manual tools. Even people who do not have professional knowledge background can easily master relevant skills, which greatly improves work efficiency and service response speed.

Not only that, this user-friendly design also helps to simplify the post-maintenance process. When periodic inspection and maintenance or parts replacement and upgrading are required, engineers can locate the fault point more quickly and accurately and implement targeted repair measures. This undoubtedly saves a lot of time and resources for enterprises, but also enhances the reliability and security level of the system.

Star products in a wide range of applications: application case studies to meet diverse needs

As a highly integrated multi-functional connecting element, this universal ring has been successfully used in many important fields and has won wide acclaim. For example, it can often be seen between various types of robot arms responsible for material handling tasks on modern automatic assembly lines. In the film and television production industry, photographers cannot do without the stable support provided by it-all lens carriers from large cranes to small aerial drones have benefited a lot. In addition, it also includes an indispensable part of the equipment list of outdoor extreme sports enthusiasts, the contribution of this "behind-the-scenes hero" can be seen in places such as climbing rope protectors or the top interface of ski poles.

Through the study and summary of these practical application cases, it can be seen that no matter how complex and demanding the requirements are, as long as the correct technology and design scheme are selected, satisfactory results can be created. This is also the source of our commitment to continuous innovation and improvement-to make every detail stand the test of time and provide customers with the most reliable products and services.

Precise and customized professional services: technical support for personalized projects

We know that different customer groups may have different specifications and sizes or other technical indicators. To this end, we have specially set up an experienced professional team to provide you with one-to-one exclusive consulting guidance to ensure that every order can be executed in strict accordance with the highest standards until the smooth delivery. Whether it is special shape cutting, non-standard thread configuration or any other form of fine-tuning modification request, we will be happy to solve all possible problems for you.

With the deep foundation and technical strength accumulated over the years, we can confidently say that there is no task that cannot overcome difficulties here. If you have any questions about selection suggestions, procurement channels or even after-sales technical support, please feel free to contact us