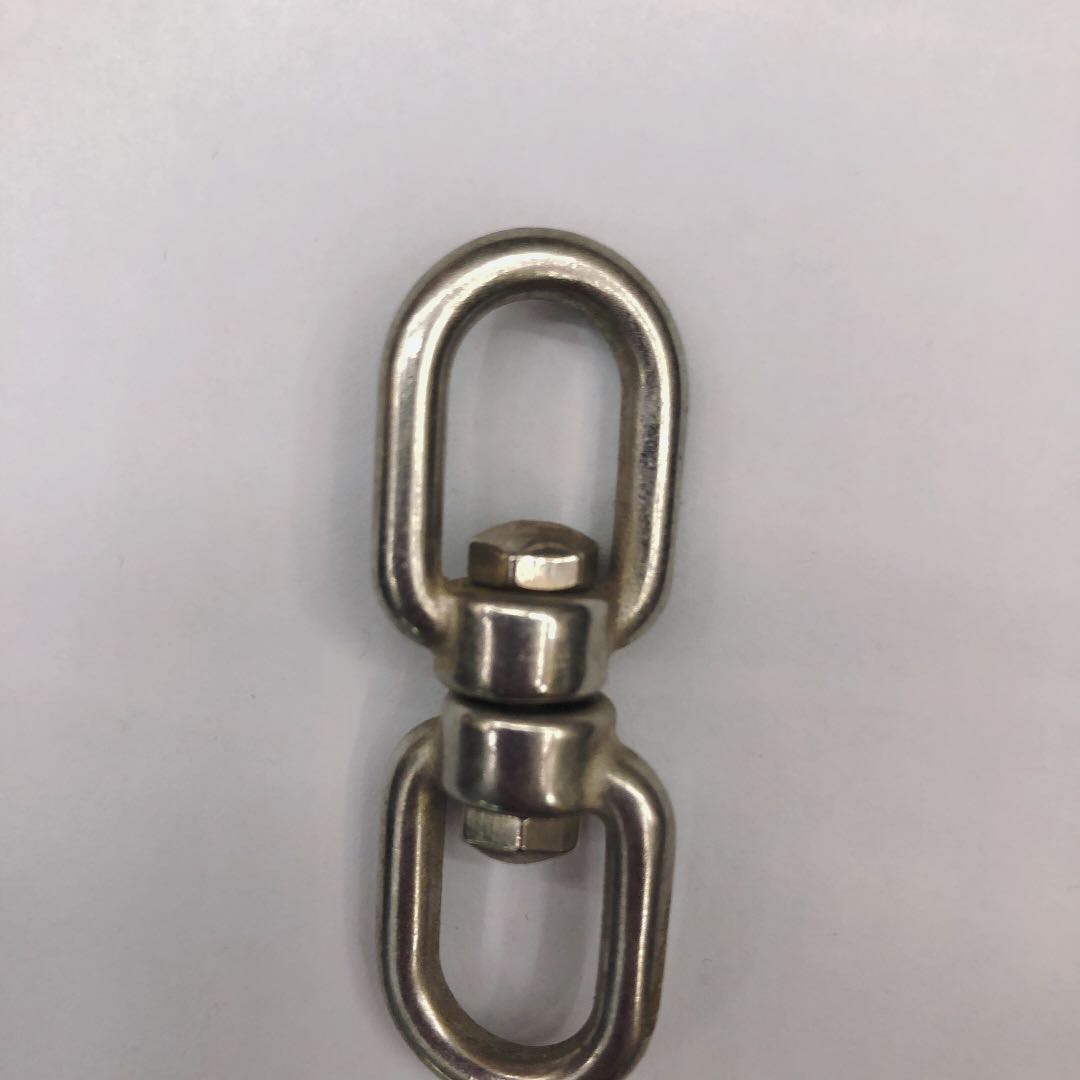

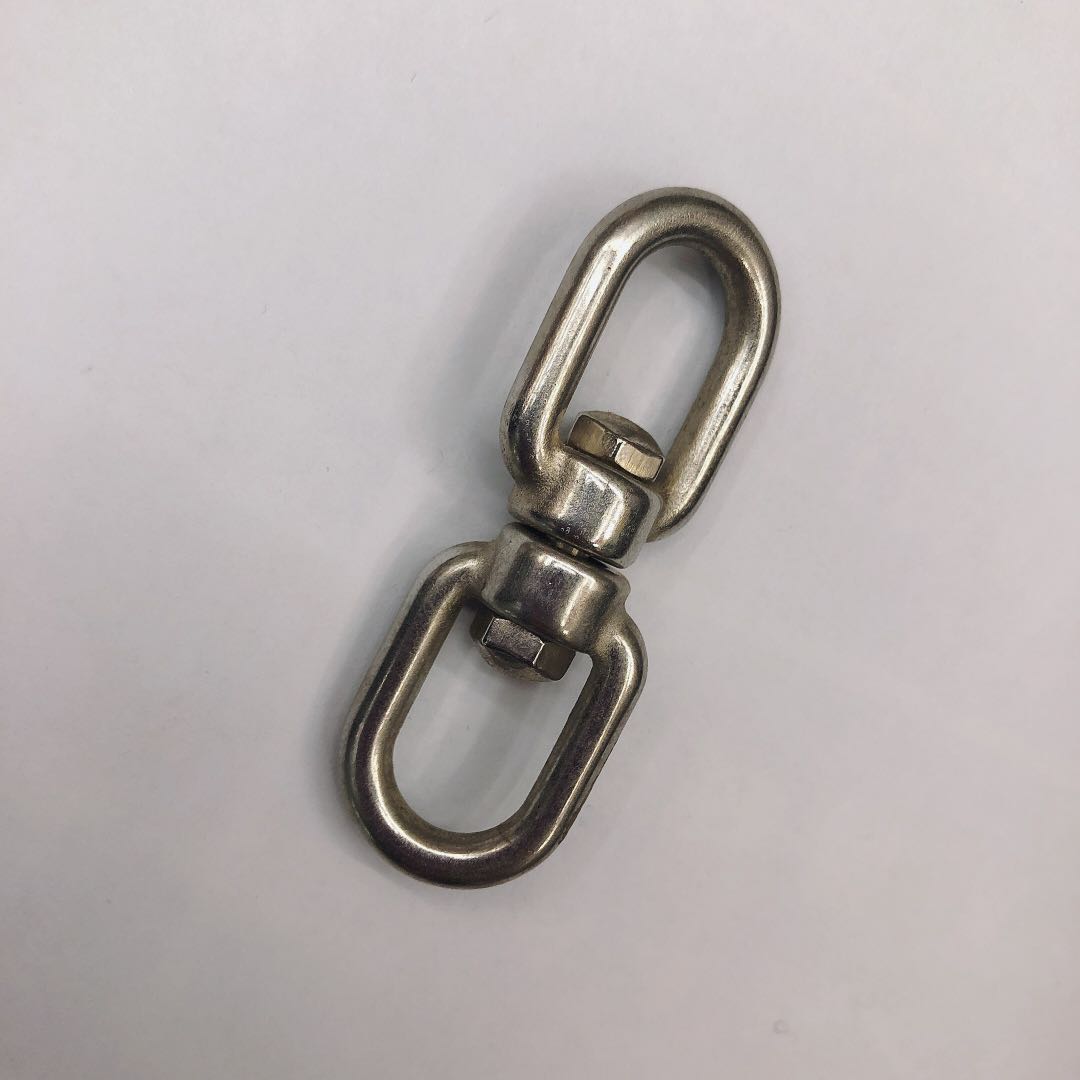

Explore high-performance gimbal 304 stainless steel rotary joints

Learn more about this specially designed gimbal ring 304 stainless steel rotary joint, its excellent performance makes it ideal for many industrial applications. This article will take you through the process and understand why it performs well in complex environments and meets high standards.

In today's highly competitive and technology-intensive industries, it is critical to find a component that is both rugged and flexible. This universal ring 304 stainless steel rotary joint stands out for its unique design and excellent performance, and has become the first choice in the minds of many engineers. Its emergence not only solves many problems of similar products in the past, but also provides a solid foundation for future innovation.

Corrosion and rust prevention: a key feature of long-lasting durability

Detailed analysis of one of the core advantages of the product-strong corrosion resistance and rust resistance. Based on the advantages of 304 stainless steel, this rotary joint can stay as long as new even in harsh environments. We will explore the specific properties and practical benefits of this material.

304 stainless steel is widely used in many fields because of its good chemical corrosion resistance. This is especially important for equipment that works outdoors or in wet conditions. This rotary joint takes advantage of this feature to ensure strength while increasing service life, reducing maintenance costs, and improving overall system reliability.

High-strength metal construction: strong and reliable guarantee

Introduce the high-strength metal materials used in the product and its manufacturing process. From the selection of raw materials to the quality control of the final product, every step is strictly controlled to ensure that a safe and reliable product is finally presented. In addition, it also involves how to achieve such a high strength standard and the technical support behind it.

In order to achieve the highest level of safety, manufacturers invest significant resources in research and development and technological improvements. The selection of top raw materials and through advanced heat treatment methods to strengthen the internal organization, thus significantly improving the overall toughness and wear resistance of the parts. This attitude of excellence allows each manufactured product to withstand extreme conditions without loss of precision.

360-degree free rotation: flexibility and stability

Demonstrate the core function of the gimbal 304 stainless steel rotary joint-full angle rotation without blocking. Through special design and precision machining, the real barrier-free rotation operation is realized, which greatly improves the working efficiency and response speed of the equipment. At the same time, the importance and potential value of this point for specific applications are discussed.

Whether it is a complex robot arm or a dynamic transmission device, it needs an ability to quickly change direction without affecting the normal operation of other components. This rotary joint fills this gap, greatly simplifying the assembly process and enhancing system coordination with its precise angle adjustment mechanism. This undoubtedly brings higher economic benefits and development potential for enterprises.

Accurate adaptation to M8 specifications: seamless docking of various systems

Describe the features of this connector specifically optimized for the M8 specification. Both installation and maintenance are very convenient, can quickly and accurately match with other components to form a complete connection system. This section also mentions more information about compatibility and other standard interface types that may be applicable.

M8 thread is one of the most common standardized sizes on the market, and it can be seen in almost all types of machinery and equipment. Therefore, when an accessory can fully meet such parameters, it means that users no longer need to worry about interchange problems or additional customization costs. And because of its wide versatility, customers can easily switch between different projects without causing inventory backlogs.

Wide application field: the right-hand man of machinery and industrial automation

Summarize the diversified uses of this product, especially its important role in mechanical equipment and industrial automation. With the advantages mentioned above, it can be widely used in various industries to help enterprises improve productivity and reduce costs. The article will