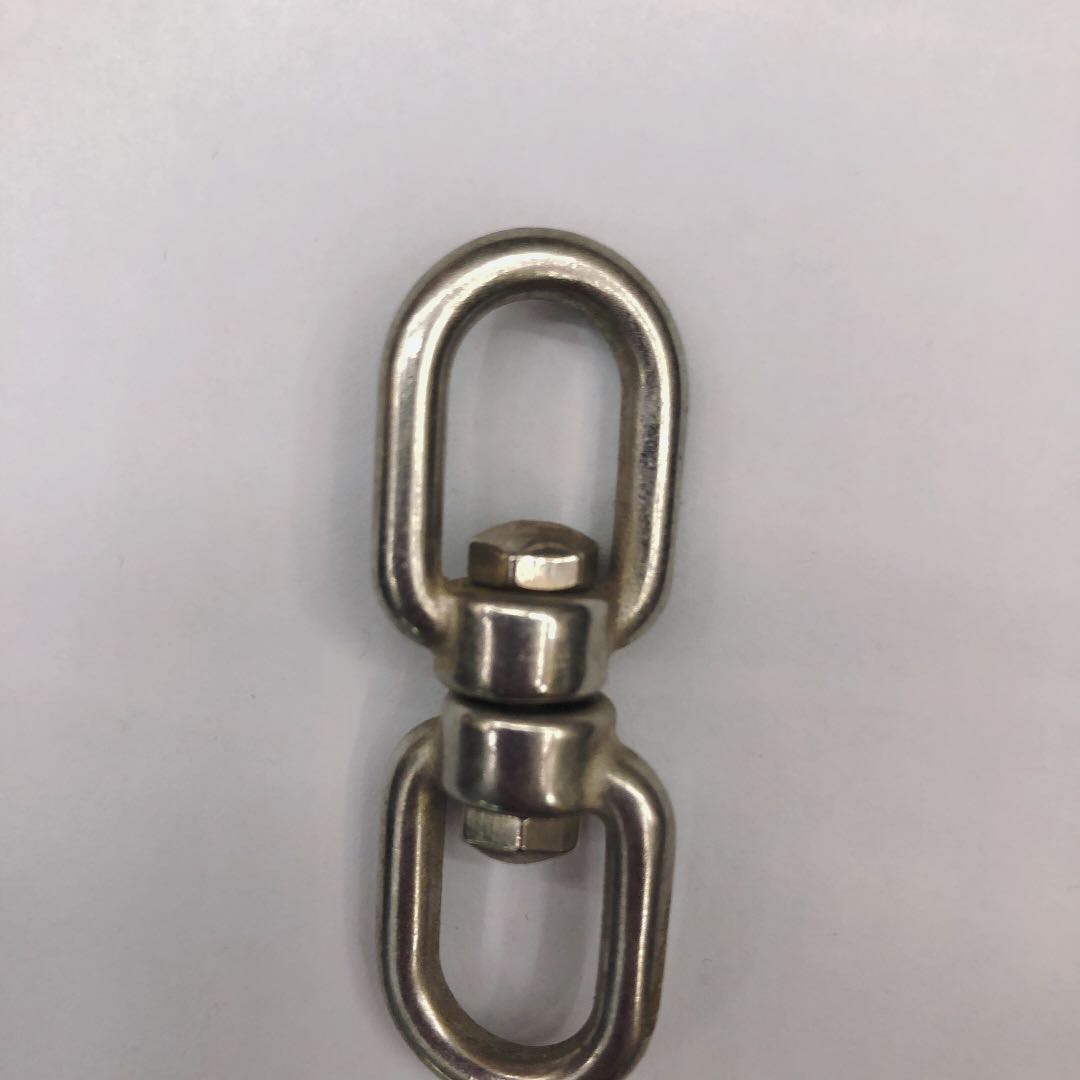

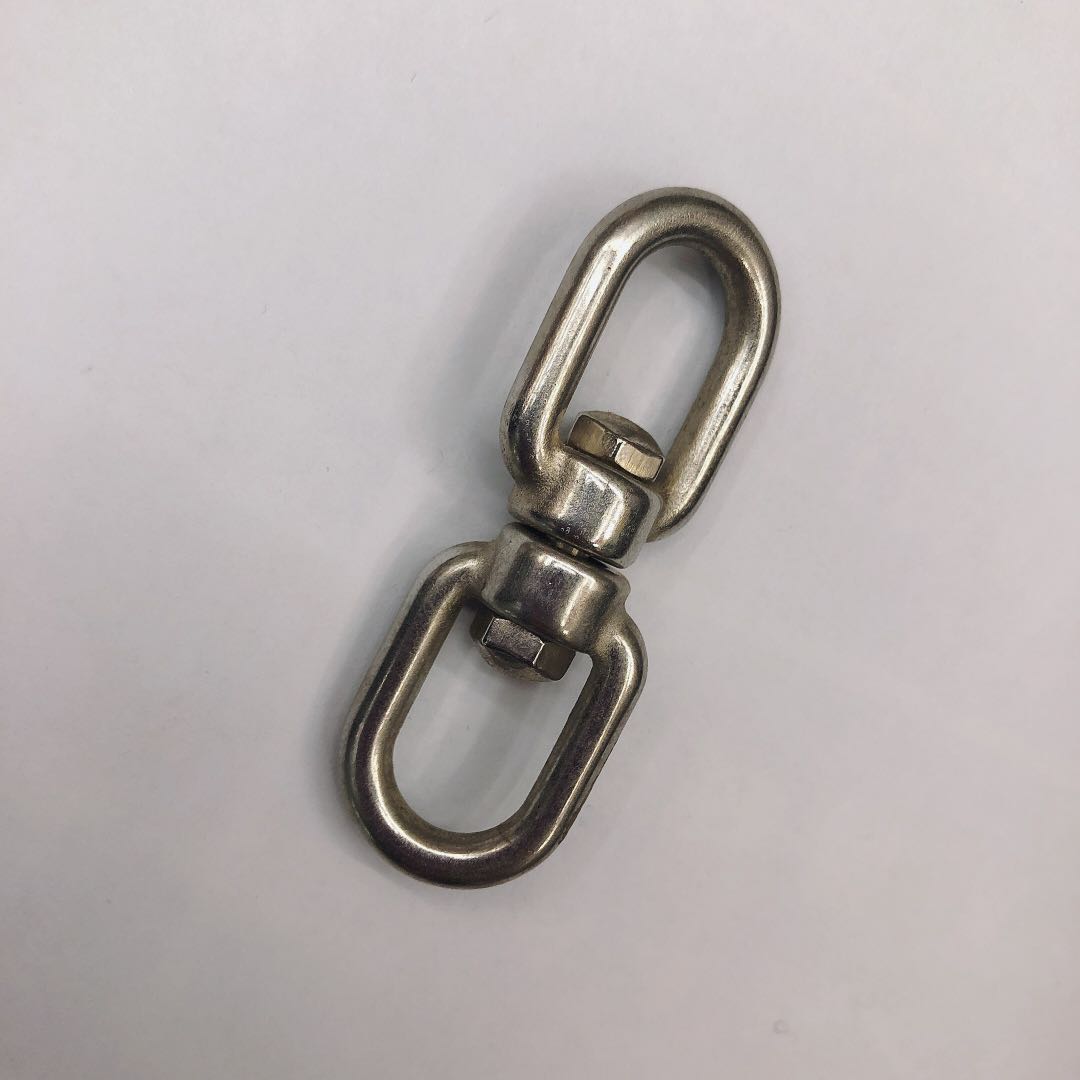

In this era of quality, every detail may determine success or failure. Especially when it comes to mechanical equipment or household assembly, choosing the right connecting parts is a key step. Today we are going to introduce such a revolutionary product-M8 connector made of high-quality 304 stainless steel and supporting 360-degree free rotation.

First, let us discuss why we chose 304 stainless steel as the main material. Compared with other metal options, it shows unparalleled advantages: excellent corrosion resistance allows it to remain intact for a long time in harsh environments; at the same time, due to the tight internal structure, it is difficult to rust even in humid air. These characteristics together ensure that the entire device can maintain the initial performance level after long-term operation.

Next, dig deeper into the wisdom behind this unique design! This connector uses advanced engineering technology to achieve a true sense of the full angle adjustable function. Whether you want to achieve seamless connection between precision instruments or efficient operation on a large-scale production line, you can rely on this innovative achievement to achieve the goal. The required orientation conversion process can be completed by simple manual adjustment, and each lock will form a firm joint to prevent loosening and falling off.

now imagine such a picture: the workers in the busy workshop are busy in a tense and orderly manner, and the tools in their hands are just one of our protagonists-an indispensable part of the automatic assembly line for industrial production; or when walking into the warm home kitchen renovation site, you can see another kind of figure active during which it is responsible for fixing the screw hole alignment of the cabinet door panel... that's right, this is why the objects we are talking about cover such a wide range of applications. Both large factories and private residential renovation projects need such high-quality accessories to assist in the completion of various tasks.

Of course, there are many people who are willing to share their valuable opinions to help later generations better understand what the actual situation is. For example, a master who has been engaged in mechanical maintenance for many years said: "Since the use of this new model, it is obvious that the work efficiency has improved by several levels and there is no longer any need to worry about frequent downtime and maintenance troubles due to damage to parts." Another amateur said that even novices without much experience can easily get started and achieve satisfactory results.

Finally, don't forget to give proper maintenance measures on a regular basis to ensure that they are always in the best working condition! It is recommended to apply a small amount of lubricating oil to the surface of the active part at regular intervals to smooth lubrication and reduce the possibility of friction loss; in addition, attention should be paid to clean up the attached dust and impurities so as not to affect the normal service life.