Exploring the charm of 304 stainless steel: why it is the preferred material for industry

Among many metal materials, 304 stainless steel stands out for its excellent performance. This alloy not only has good strength and toughness, but also has excellent corrosion resistance and oxidation resistance, making it an indispensable and important part of many industries. In particular, equipment parts working in harsh environments need to rely on it to ensure long-term stable operation without easy damage.

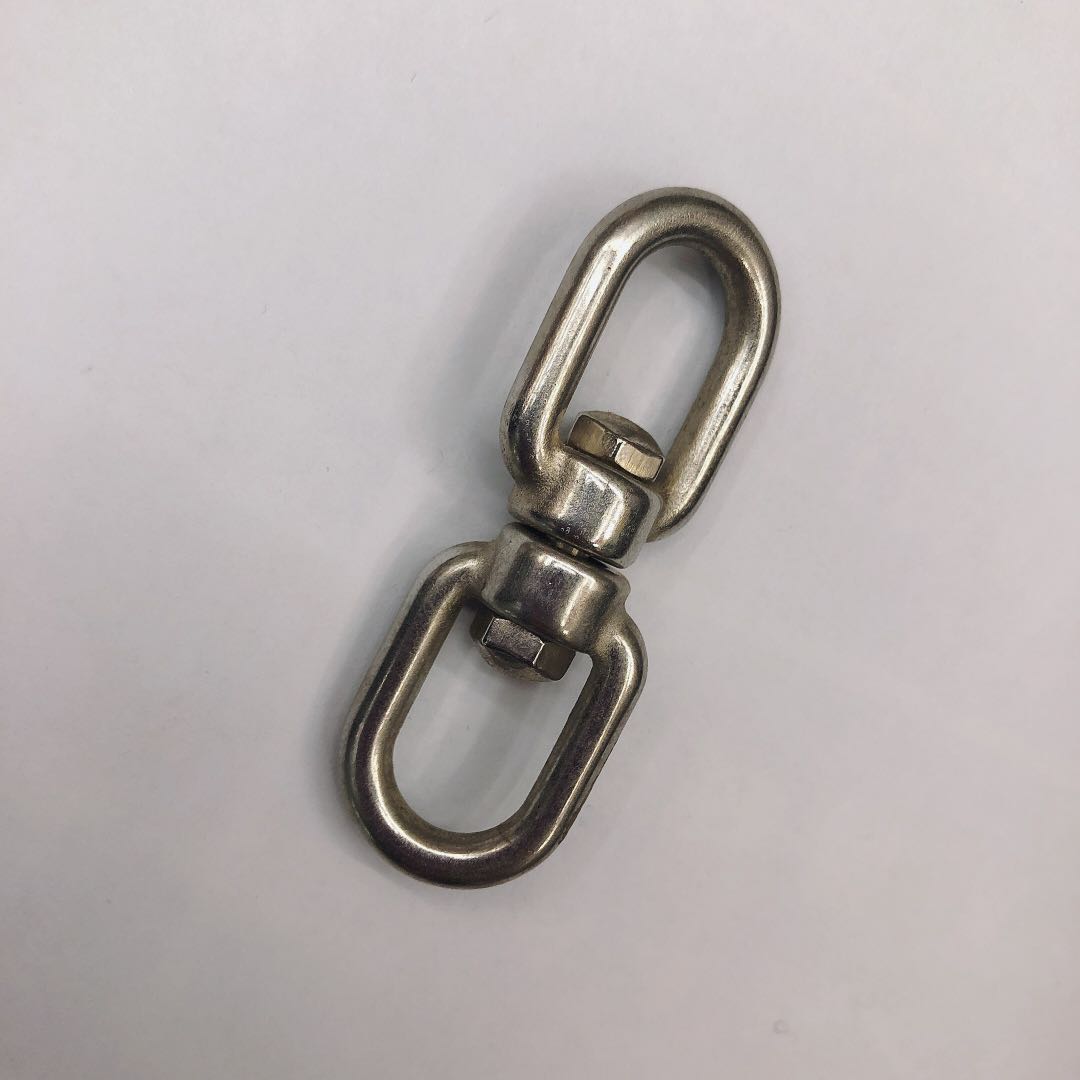

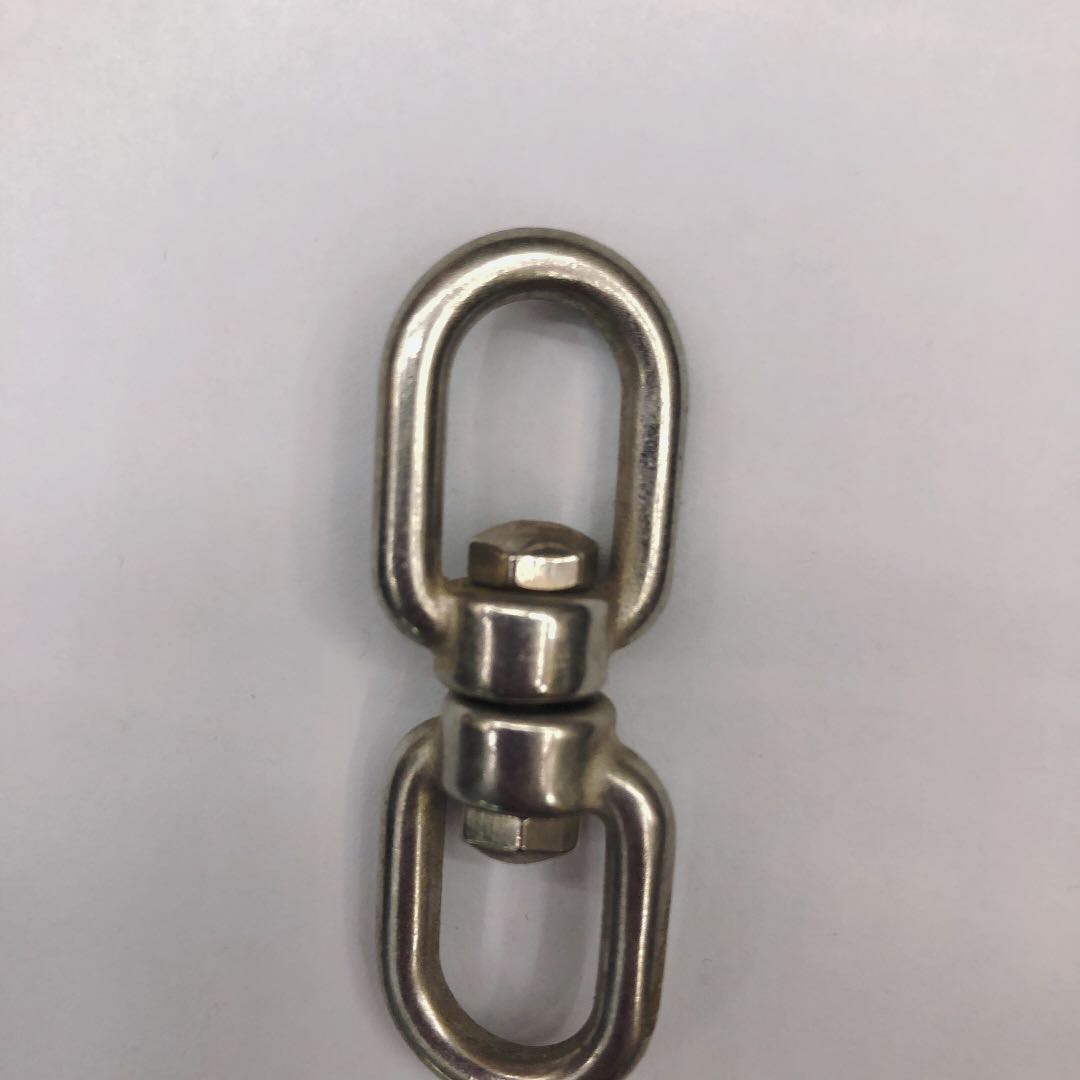

The core value of the universal rotary joint: flexible response to various complex working conditions

Flexibility is essential for modern mechanical systems to better adapt to changing working conditions. Our universal rotary joint is designed for this reason-it can realize all-round free rotation to adjust the angle position and other functional features, making the assembly and debugging process extremely simple and fast. At the same time, it can effectively reduce the probability of friction loss between components and thus improve the overall work efficiency level.

From corrosion resistance to high strength: Explain the technical highlights of the M8 connector

M 266.66cm inch as one of the international common standards are widely used in all kinds of precision instruments. This product adopts advanced surface treatment technology to further enhance the uniformity of the thickness and density of its external protective layer. In addition, the internal structure is compact and reasonable layout and other factors have formed a very strong and durable overall solution to choose from.

Real user feedback: see how this connector solves practical problems

Many customers gave a high evaluation after purchase, saying that the quality and practicality of this product are far beyond the expected imagination. "The problem of water leakage and oil leakage at the pipe connection that has been bothering me before has finally been completely cured," said an engineer from the manufacturing field excitedly. "Since it was replaced by the metal corner fitting with anti-corrosion characteristics produced by your family, there has been no similar failure."

How to correctly install and maintain the key skills to extend the service life

In order to get the most out of this high quality universal rotary joint, be sure to follow the relevant instruction manual for the standard operating procedures. For example, first check whether all screws are tightened in place and then start the trial operation phase to observe whether there is abnormal noise, vibration, etc. Once problems are found, stop the operation in time to find out the causes and eliminate hidden dangers, and then continue the next work plan until it is completely confirmed that there is no bad condition before it can be officially put into service in the service environment for a long time.