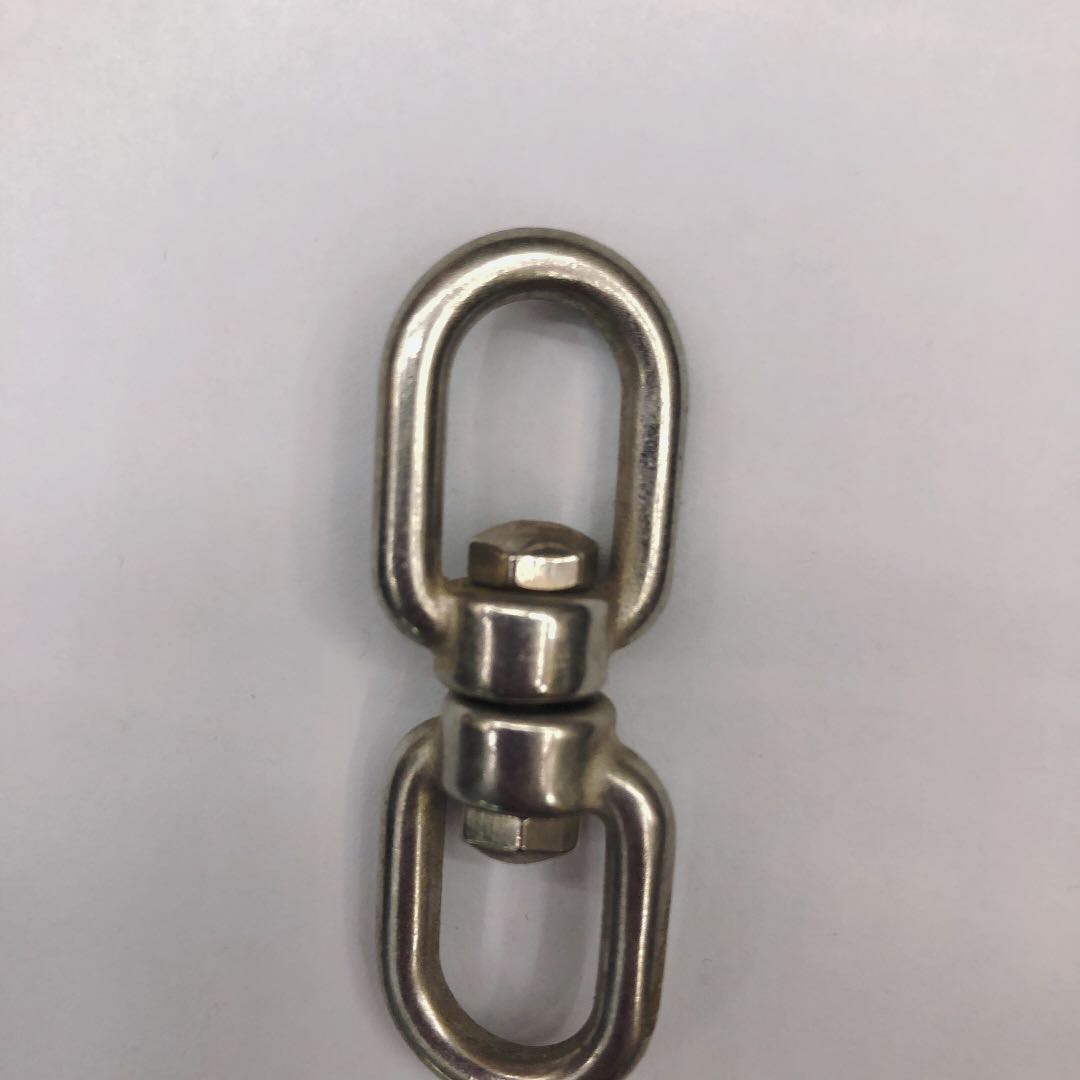

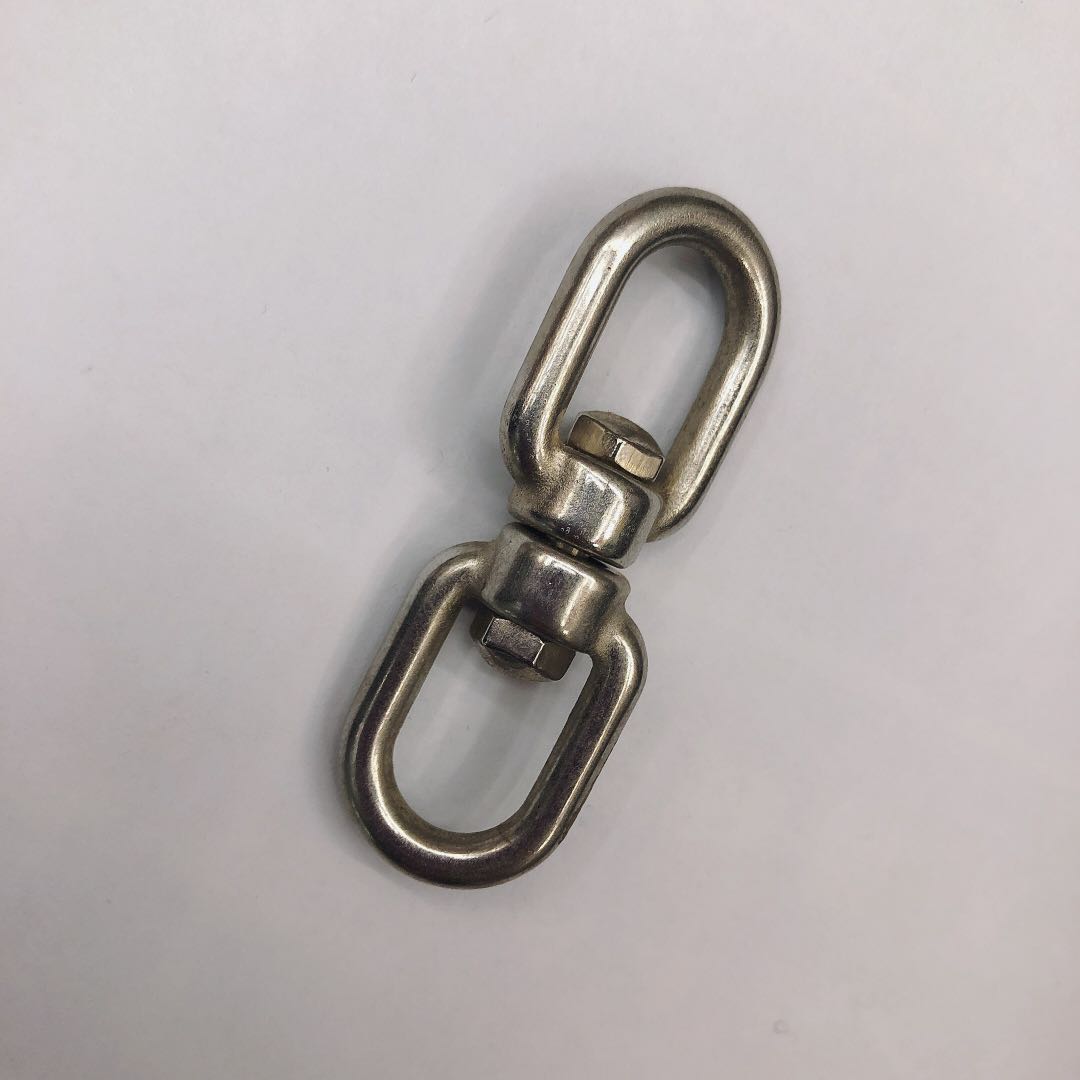

In the industrial field, small parts can determine the operating efficiency and service life of the entire system. Today we are going to introduce such a "hero behind the scenes"-a high-performance universal rotary joint made of 304 stainless steel.

This product has become the first choice of many engineers for its excellent performance.

The reason why it can stand out in the market is due to the top materials and technical processes it uses. 304 stainless steel not only has strong corrosion resistance, but also performs well in the face of harsh conditions such as acid, alkali and salt; at the same time, its mechanical strength is also very high, and it can withstand greater pressure without deformation or rupture. In addition, the surface after precision processing is smooth and delicate, which further extends the life of the product and reduces friction resistance.

So what exactly is a truly excellent universal rotary joint? In addition to the basic requirements mentioned above, the following aspects need to be considered:

Precise angle adjustment: The ability to rotate freely is one of the core functions of this type of part. Our new model supports complete 360 ° all-round flexible operation to meet the needs in any direction.

M8 standardized size design: unified standard is convenient for compatible use with other components, simplifying the assembly process and improving work efficiency.

Lightweight construction concept: Although made of durable steel, we still control the weight within a reasonable range, making handling and installation easier and more convenient.

Every detail is carefully polished to give the user a more perfect experience.

Perhaps you will be curious about where such a small object can play a role? In fact, it has already been found in various industries. For example, it is responsible for the transmission of fluid media in automated assembly line operations; or it is applied to medical devices as a connection hub and so on. With stable quality performance and diversified adaptation options, I believe you will agree that it is one of the best partners to solve the problem.

Of course, just buying it back isn't enough! The correct implementation of installation procedures and regular inspection and maintenance are also essential. First of all, it is necessary to ensure that all interfaces have been cleaned up and no impurities remain, and then tighten the screws in turn according to the order indicated in the instructions until the appropriate tightness is reached. The next step is to conduct periodic appearance inspections to check whether there are cracks and leaks, and take timely measures to repair and prevent potential risks from spreading.

With one investment and long-term benefits, the ideal partner you can trust is waiting for you.

In summary, choosing a universal rotary joint made of 304 stainless steel is definitely a wise move. Whether it is short-term mission execution or long-term planning layout can provide strong support and guarantee services, why not? Take action now, let us witness this power from technology to change the beautiful moments of life every day.