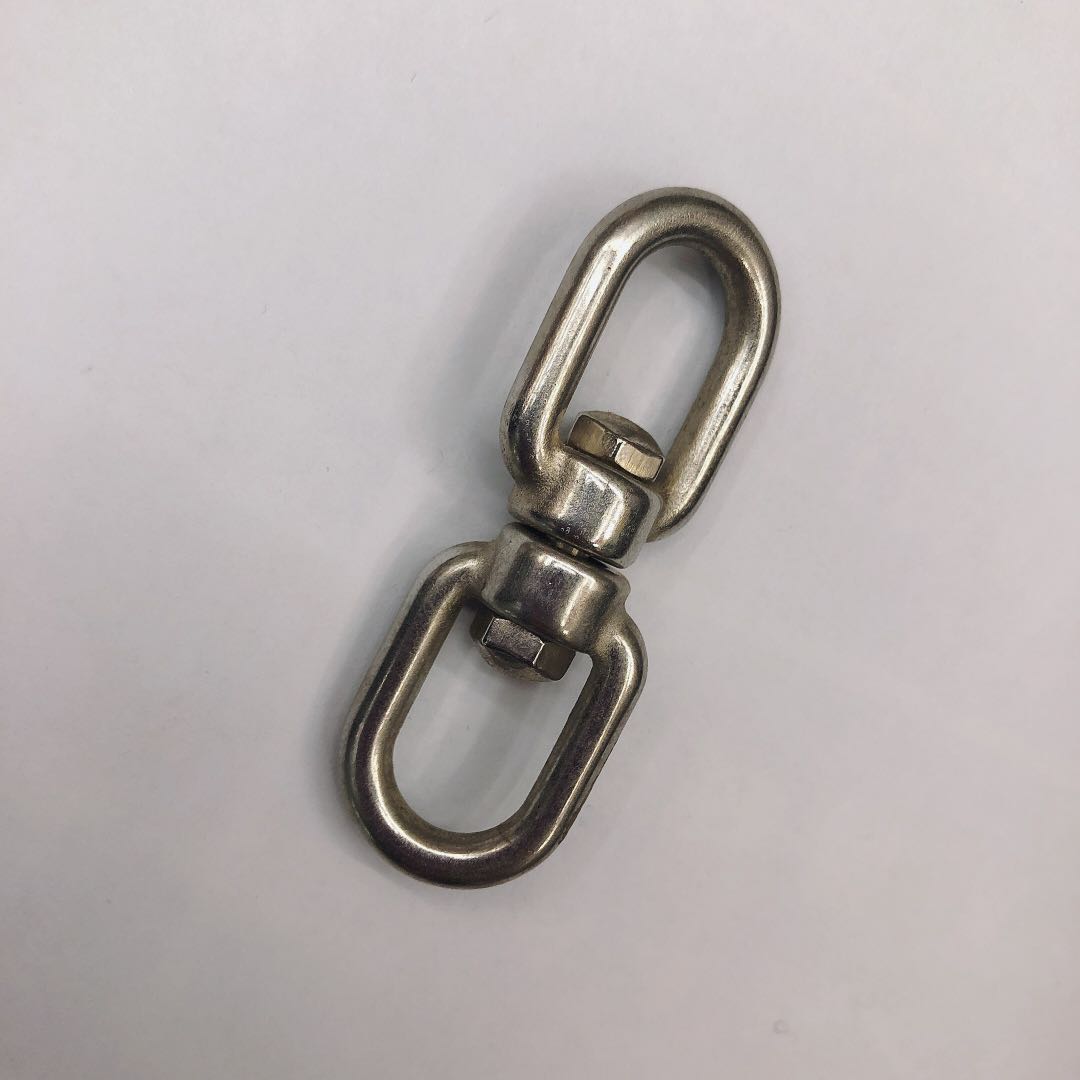

When a durable and reliable connection is needed to cope with complex environments, the universal rotating ring made of 304 stainless steel is undoubtedly an excellent choice. Its high performance makes it an ideal companion for many industrial projects.

Why 304 stainless steel has become the preferred material for industry

As a kind of steel widely used in the world, 304 stainless steel stands out in many fields due to its excellent corrosion resistance and mechanical strength. This material can not only resist the influence of most chemical substances and the natural environment, but also maintain stable physical properties for a long time. This means that products made from the material perform well even under extreme conditions.

In-depth analysis of the key advantages and application scenarios of the universal rotating ring

Our 304 stainless steel universal rotating ring adopts advanced technology and high-standard production process, with the following key highlights:

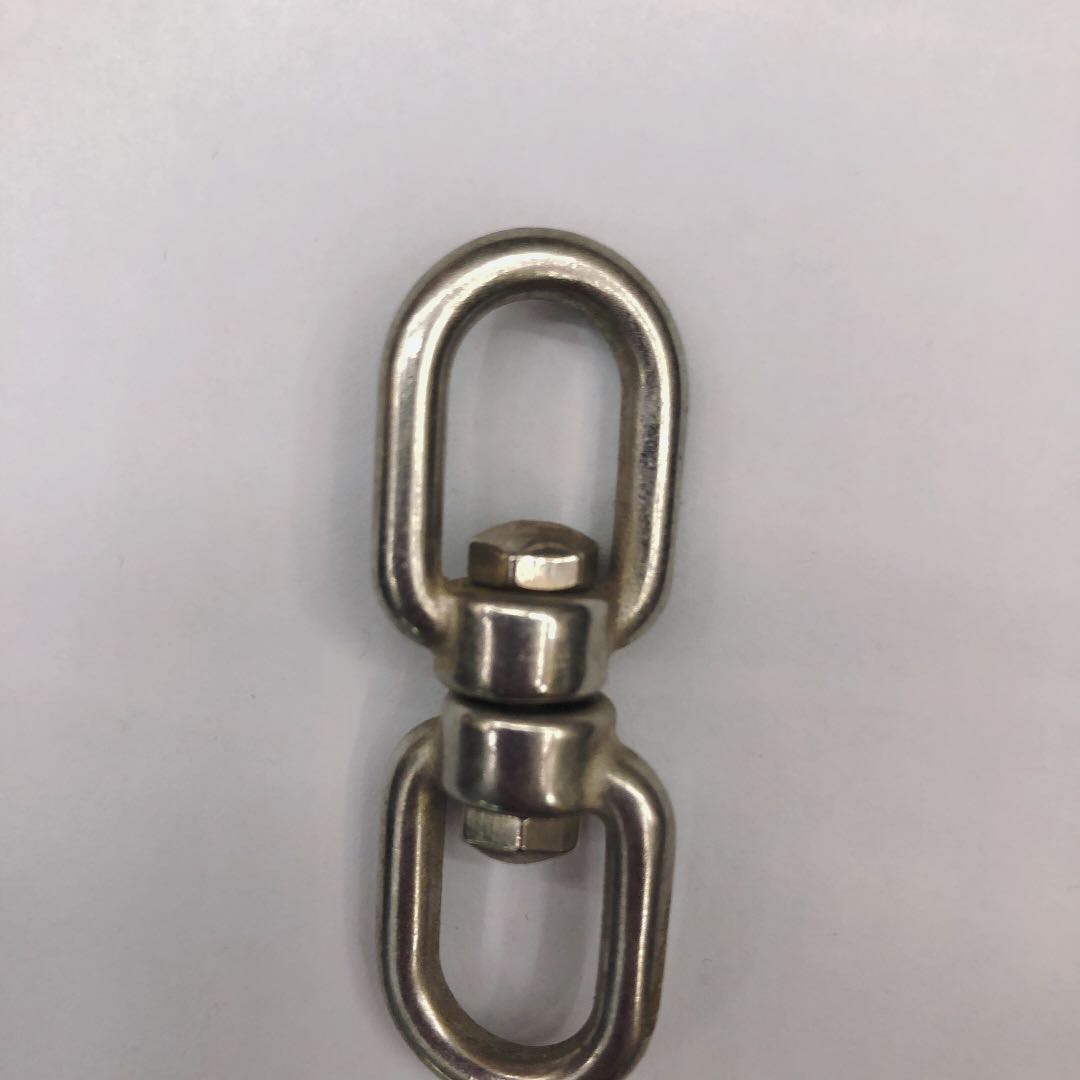

- - **All-round flexibility**: Thanks to its unique design, this part can achieve smooth 360 ° rotation without dead corners and adapt to a variety of dynamic operation requirements.

- - **High reliability**: Durable and easy to maintain, it is particularly suitable for equipment that requires frequent use.

- - **Broad compatibility**: The standard M8 interface specification facilitates seamless integration with other systems, simplifying the installation process and reducing costs.

How to complete efficient installation and debugging in simple steps

In order to help users get started with this powerful tool more easily, we have prepared a concise operation guide:

- First confirm whether the selected model matches the parameters of the target system, and check whether all accessories are complete and intact.

- Connect the two ports correctly according to the instructions, and pay attention to apply appropriate force to avoid damaging the surface treatment of the part.

- Start the test run program to verify the smoothness of operation and the presence of abnormal noise.

Following the above guidelines can greatly reduce the probability of errors and shorten the initial deployment time period.

Customer case sharing: looking at the significant benefits brought by actual use

Mr. Zhang is an engineer at a well-known manufacturing company. He recently introduced this 304 stainless steel universal rotating ring into the production line transformation project. "Since the replacement of the new model," he said, "the efficiency of material handling has increased by nearly 20% throughout the assembly line, and the frequency of maintenance has been greatly reduced." This fully proves the real value of this product.

Care and maintenance tips: the best way to extend product life

Although the rotating ring itself is strong and durable enough, proper care measures can still help further extend its service life. For example, regular cleaning of exposed parts to prevent the accumulation of dust particles caused by wear; In addition, timely application of special lubricating oil also helps to ensure that the moving parts are always in good condition.