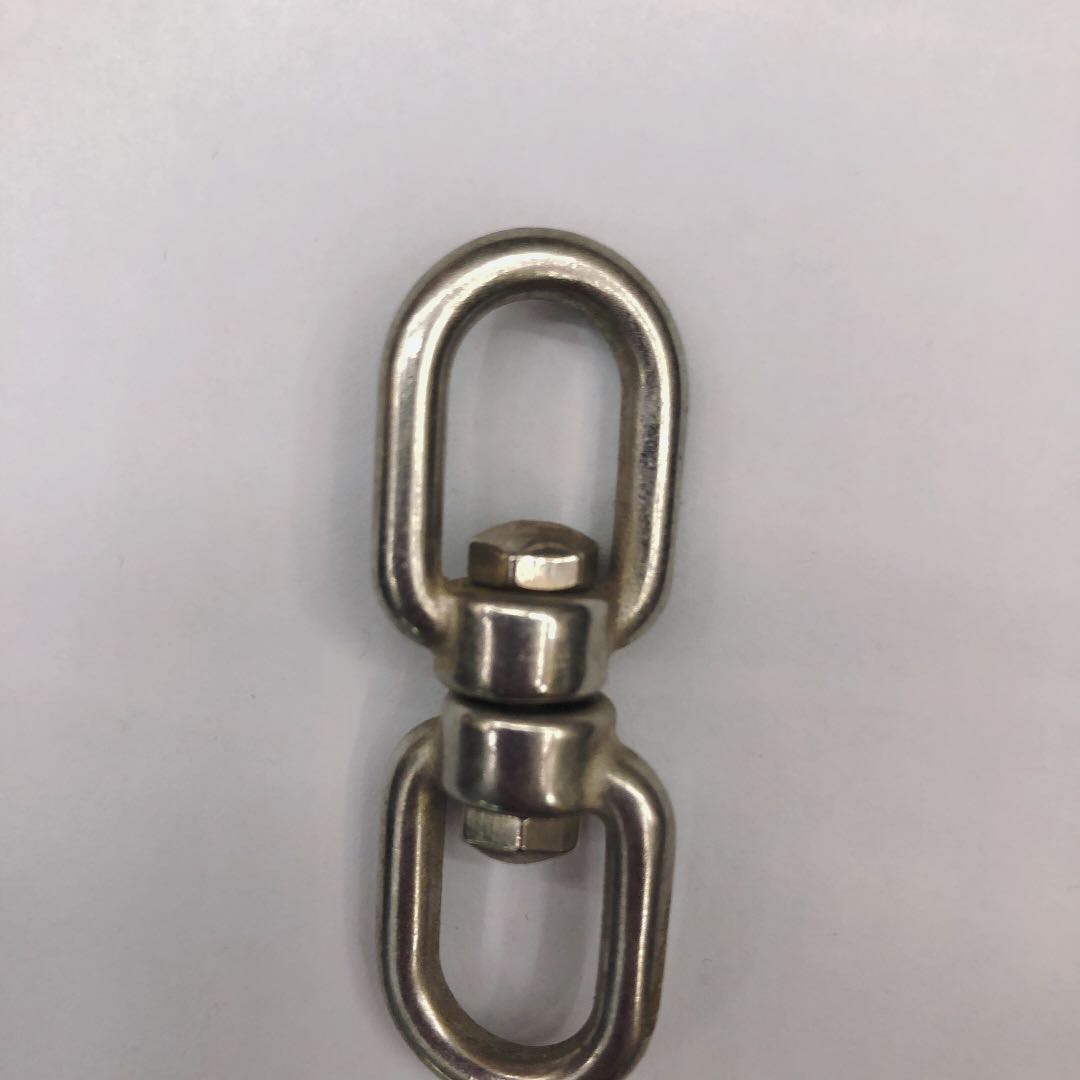

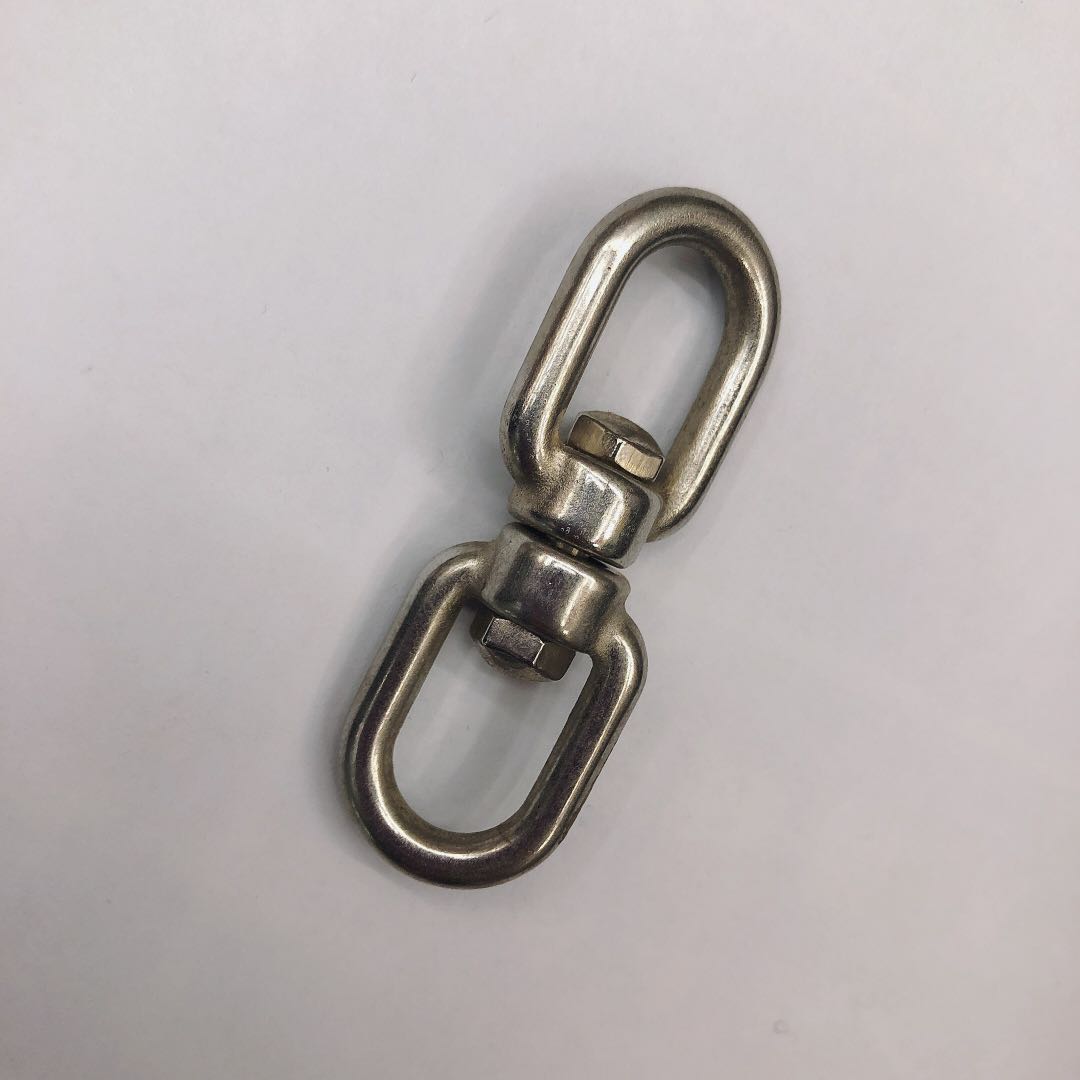

In industrial production and daily life scenarios, a high-performance connection device can significantly improve efficiency and extend equipment life. Today we will learn more about a special product-high quality 304 stainless steel universal rotating ring.

Understand the charm of 304 stainless steel: why it is the ideal material for the universal rotating ring

As one of the globally recognized high-quality steels, 304 stainless steel not only has excellent strength but also has excellent corrosion resistance. This material is not easy to rust and can maintain excellent performance in extreme environments, making it the best choice for manufacturing high-end mechanical parts.

Reveal the secret of efficient 360-degree rotation design and its practical application scenarios

The core advantage of this product is its revolutionary 360-degree rotation function. This feature greatly simplifies the workflow and reduces the risk of failure, whether in lifting or automated production lines. For example, when lifting large objects, precise positioning can be easily achieved by adjusting the angle.

Advantages of M8 interface: the choice of stability and flexibility

M8 standard thread aperture not only ensures sufficient firmness but also takes into account the convenience of installation and disassembly, and is suitable for most commonly used tools. This design allows the user to quickly replace or adjust the relevant components according to specific needs without any difficulties.

Detailed explanation of corrosion-resistant and rust-proof technology: core competitiveness of durable products

In addition to top-of-the-line ingredients, we also work hard on the surface treatment process. After special coating processing parts even long-term exposure will not be easily damaged by erosion, thus greatly extending the service life.

How to choose the right universal rotating ring? Professional buying guide answers your questions

When faced with a dazzling array of options, it is easy to feel confused. At this time, you need to master several key indicators to make judgments. The first is to confirm whether the required bearing weight range is matched; the second is to check the compatibility parameters such as screw size and so on. Only by considering these aspects can we pick the ideal model that is really suitable for our project.

Real User Feedback: See how they solved the problem with this product

Mr. Zhang is a professional engaged in stage construction. "Since the adoption of this new model, the work efficiency has more than doubled!" He sighed. "It used to take a lot of time to calibrate the position every time. Now everything has become so simple." Similar praise and a lot of good news from customers from all walks of life to further verify the strength of this product.

Maintenance and maintenance tips: keep your universal rotating ring in peak condition all the time

Although our products are of high quality, we still need to take necessary care measures on a regular basis to ensure that they are always in the best operating condition. It mainly includes timely removal of dirt to prevent foreign matter from jamming the moving parts and timely application of lubricating oil to reduce friction loss and other operation steps are very important and cannot be ignored ~