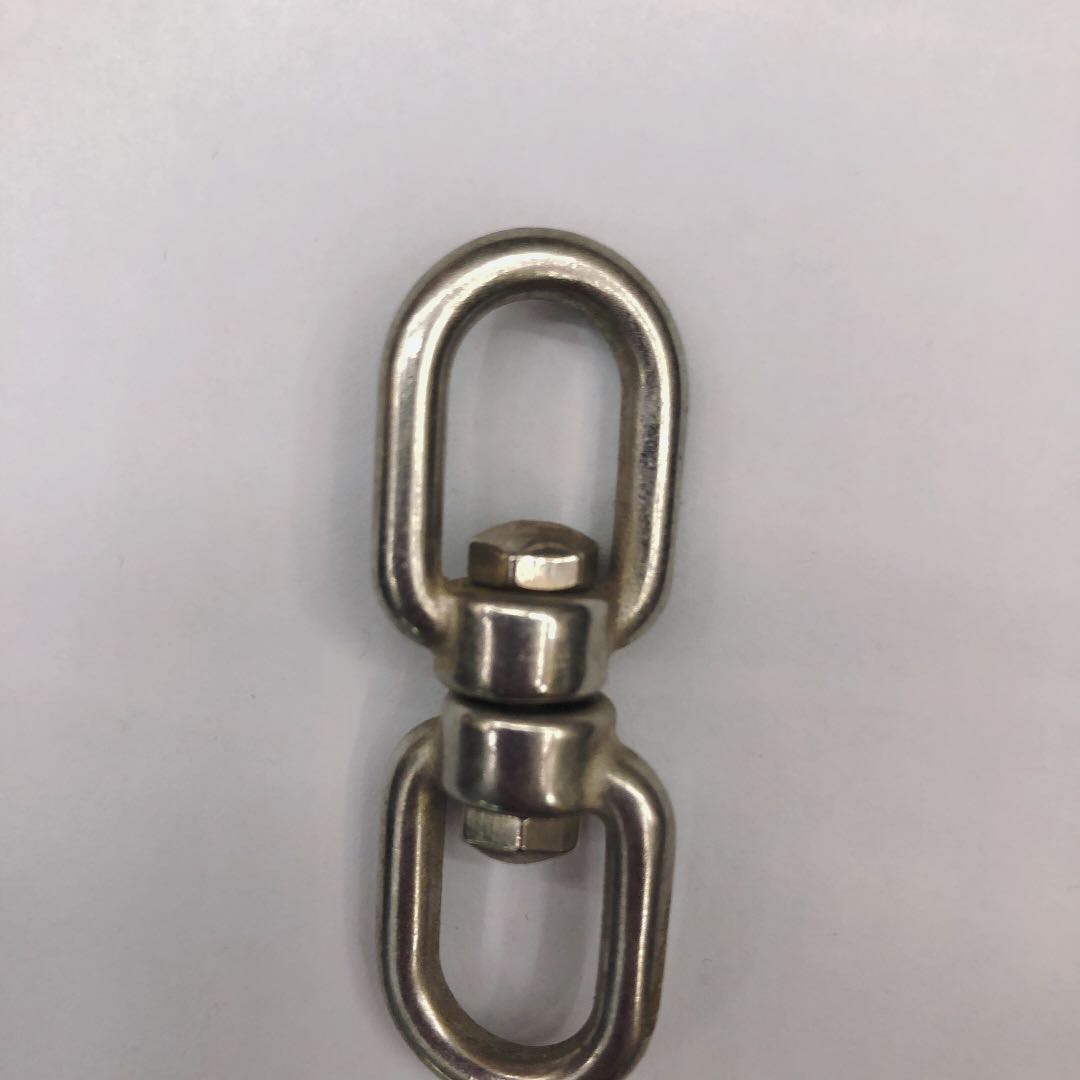

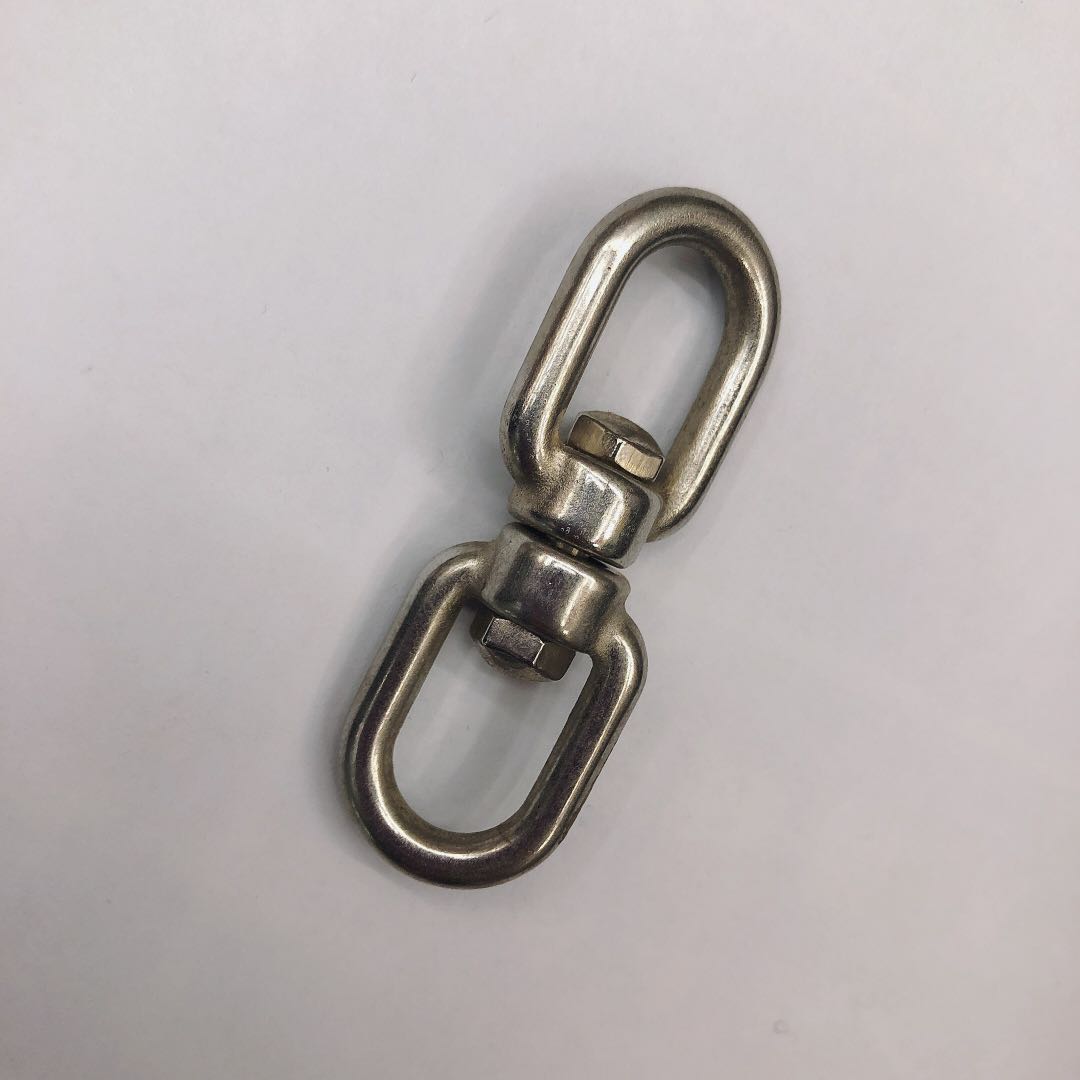

As a key component in industry and daily life, the high quality 304 stainless steel universal rotating ring stands out with its unique characteristics and wide applicability. Next, we will take a closer look at its material advantages, design features, and how it adapts to various scenarios.

Durable Material Analysis: Why 304 Stainless Steel?

The gimbal ring made of 304 stainless steel exhibits excellent corrosion and rust resistance, thanks to the balanced ratio of chromium and nickel in its chemical composition. This characteristic makes it maintain its original luster and strength even in humid or salt spray environment, and is widely used in chemical industry, marine engineering and other fields.

In addition to excellent corrosion resistance, 304 stainless steel also has high mechanical strength and can withstand large pressure loads without deformation and fracture. Therefore, it is the ideal choice for many precision instruments and heavy equipment connectors.

The secret of flexibility: the advantages of 360-degree omnidirectional rotation design

One of the most significant features of this product is the realization of a true 360-degree all-round rotation without dead corners. This design can not only greatly reduce the frictional resistance caused by angle changes, but also greatly improve the degree of freedom of movement, so that the entire system operates more smoothly.

For example, in an automated production line, this feature can be used to easily adjust the position and direction of tooling and fixtures, thus optimizing the processing process and improving work efficiency.

For example, in an automated production line, this feature can be used to easily adjust the position and direction of tooling and fixtures, thus optimizing the processing process and improving work efficiency.

Accurate adaptation: the value of M8 standard interface

The design of the M8 standard interface further enhances the practicality and universality of this product. As an international general specification, it is suitable for almost all parts assembly work in related fields. Whether you are engaged in car manufacturing or building construction, you can easily connect other supporting components to it.

In addition, standardized interfaces help shorten the installation and commissioning cycle and reduce the probability of errors, saving companies a lot of time and cost.

Multi-scenario application: from industrial manufacturing to home DIY application case sharing

This universal rotating ring is not only limited to professional applications, but also provides convenient services for ordinary users. For example, in the maintenance of household appliances, it can be used to re-fix loose pipes; and in outdoor camping activities, it can be used as a joint device between tent brackets.

Another interesting example comes from the aspect of artistic creation-some sculpture artists will embed it in their works to achieve dynamic display effect, so that static works of art will glow with new vitality.

Selection tips and maintenance suggestions: the key method to extend the service life

In order to better play the potential of this product, we should fully consider our own needs before purchasing, and clarify the required load capacity and rotation range and other parameter requirements. At the same time, we should also pay attention to the quality of surface treatment to ensure that there are no obvious scratches or burrs.

It is important to regularly remove dust and debris and apply lubricant to the core during later use. If any abnormal situation is found, it should be shut down for maintenance in time to avoid greater losses.