leading industrial innovation: 304 stainless steel universal ring, opening a new era of efficient production

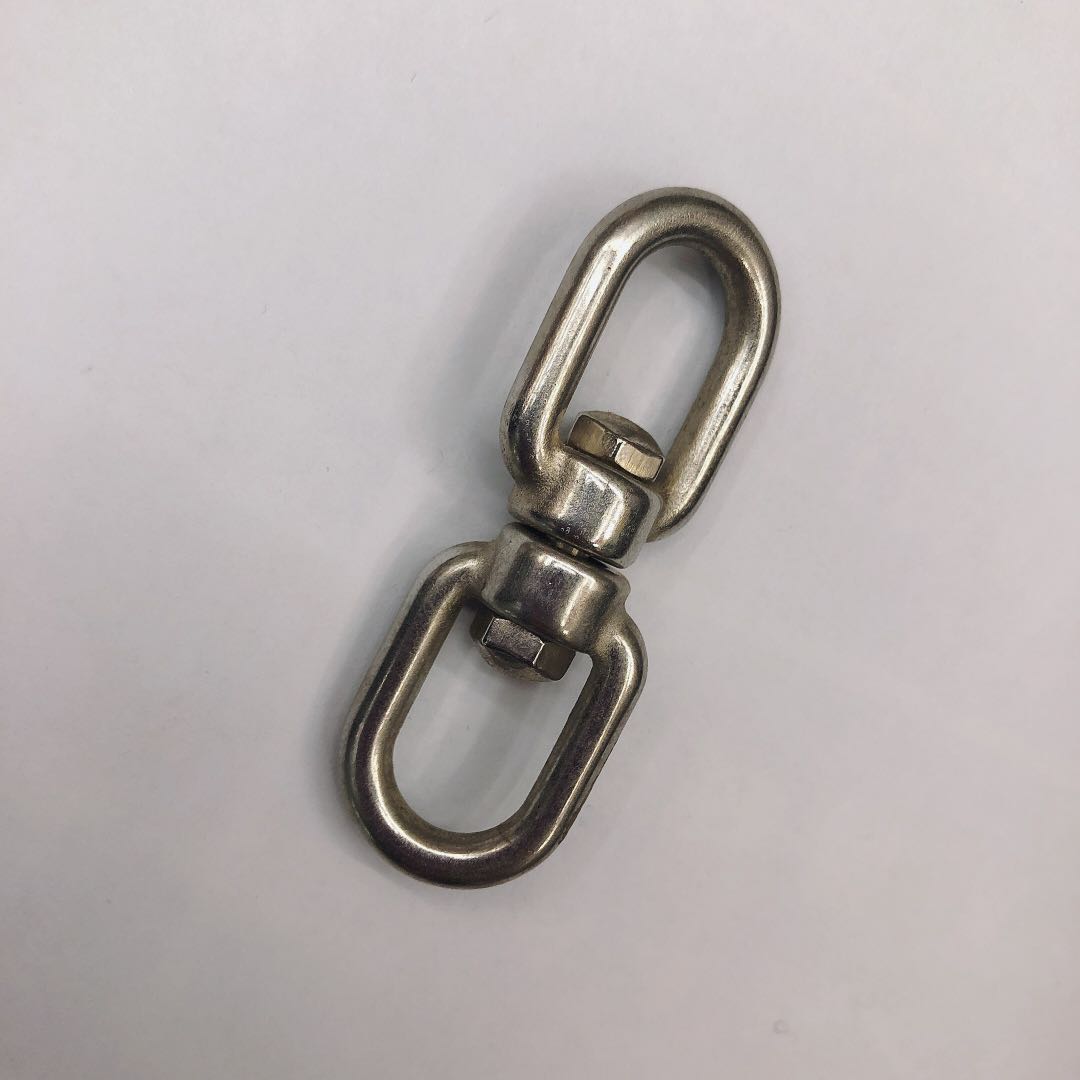

In today's highly competitive market environment, every technological innovation may become the key to success. Today, we want to introduce to you is a revolutionary industrial accessories -304 stainless steel high-strength universal ring, it not only has excellent corrosion resistance, but also can adapt to a variety of extreme conditions of high-strength operations, is undoubtedly to promote the efficiency of industrial production a big weapon.

Beyond the limit: the industrial miracle of corrosion resistance and rust prevention

In the face of complex industrial application scenarios, the durability of products is particularly important. Our 304 stainless steel universal ring adopts advanced corrosion-resistant and rust-proof treatment, which can operate stably in harsh environments such as acid and alkali, humidity and even salt spray for a long time, greatly extending the service life and reducing maintenance costs. This means that even in the chemical industry, marine engineering and other fields, it can ensure the safe and reliable operation of the equipment.

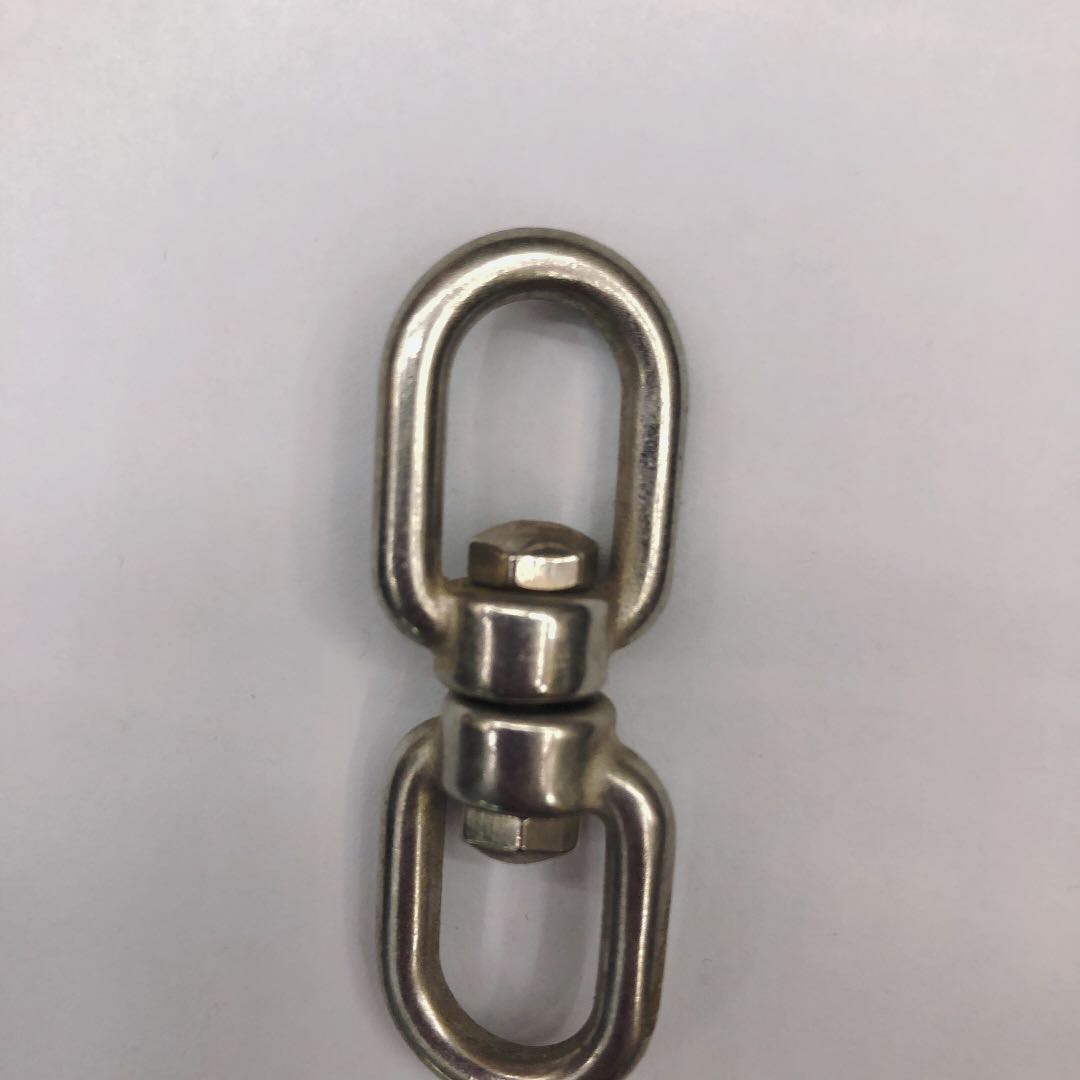

Limit rotation: 360-degree omnidirectional free connection

Flexibility is the soul of mechanical design. The 360-degree omni-directional rotation function of the 304 stainless steel universal ring completely solves the problem of the angle limitation of the traditional connector, making the docking between the equipment more smoothly and freely. This dead-angle-free rotation capability not only significantly improves the assembly speed, but also provides great convenience for more complex pipeline network layouts.

Quick installation: M8 specification, simplified operation process

In a fast-paced industrial production line, time is money. To this end, we have specially designed the M8 specification of the fast metal interface, to ensure that the installation and removal of the universal ring becomes extremely simple and quick. Workers can complete precise docking without cumbersome tools, which greatly saves manpower and material resources and improves overall work efficiency.

Application Case: Practical Results from Workshop to Field

From the robot arm connection on the factory assembly line to the piping system of outdoor heavy equipment, 304 stainless steel gimbal rings are found all over the world. Here are a few typical application examples that demonstrate the product's excellence in a real-world operating environment.

- after the introduction of this product in an automobile factory, the replacement time of parts on the assembly line has been shortened by nearly 30%, effectively reducing the situation of downtime and waiting for materials, and the production capacity has been greatly improved.

- An offshore oil platform operator used this gimbal to replace the original standard accessories, successfully resisting the erosion of salt in the sea, extending the service life of the facility and saving huge maintenance costs.

- In the food processing industry, its excellent hygiene performance has been unanimously recognized, especially in the cleaning and disinfection process, without worrying about the risk of product contamination caused by residual stains.

Conclusion: A Solid Step Toward Higher Productivity

The 304 stainless steel high-strength universal ring is not only as simple as connecting two objects, but also a symbol of technological innovation in the industrial field. With excellent quality, excellent adaptability and convenient operation, it is gradually changing the rules of the game in the traditional manufacturing industry. If you are also eager to enhance the competitiveness of your own enterprises, you may as well consider incorporating this universal ring into your supply chain system to witness the birth of the next industrial miracle.

Learn more, I .e.