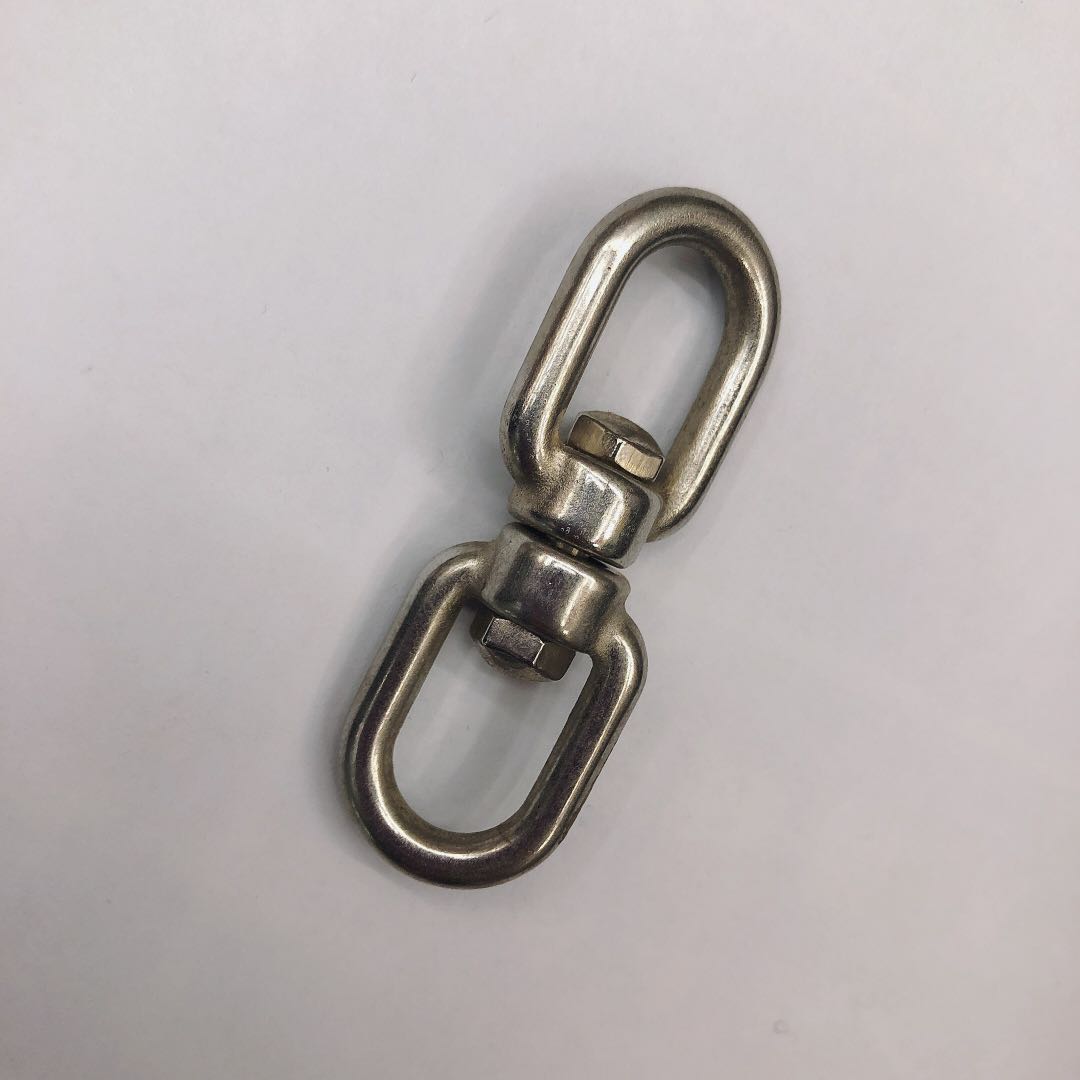

Tough and durable material guarantee

Learn more about why 304 stainless steel was chosen as the main material for this universal rotating ring. Discuss its excellent physical properties and chemical stability, and explain how these characteristics make it an ideal choice in complex environments. At the same time, discuss the brand's high standards in material selection and commitment to quality control to ensure that each component meets the highest standards. 304 stainless steel is known for its excellent strength, toughness and oxidation resistance, and can maintain stable mechanical properties in extreme temperature ranges. This makes it ideal for parts that need to withstand high pressure, impact loads and long-term exposure. The manufacturer always adheres to strict production process management and regularly conducts third-party testing and certification to ensure that all products manufactured from the factory meet the requirements of international safety regulations.

Excellent corrosion resistance

Detailed analysis of the strong anti-corrosion properties of 304 stainless steel, especially in salt spray, acid and alkali solutions and other harsh conditions. Examples of practical application scenarios, such as chemical plant piping systems or mechanical equipment in the marine environment, highlight their reliability and long life advantages. Due to the high proportion of chromium, 304 steel can form a dense oxide film on the surface, which can effectively prevent the penetration of chloride ions and cause pitting corrosion. Therefore, when used in coastal areas or chemical production workshop, it can still maintain good working condition for many years without deterioration and damage. This durable quality not only reduces maintenance costs, but also provides customers with a more peace of mind service experience.

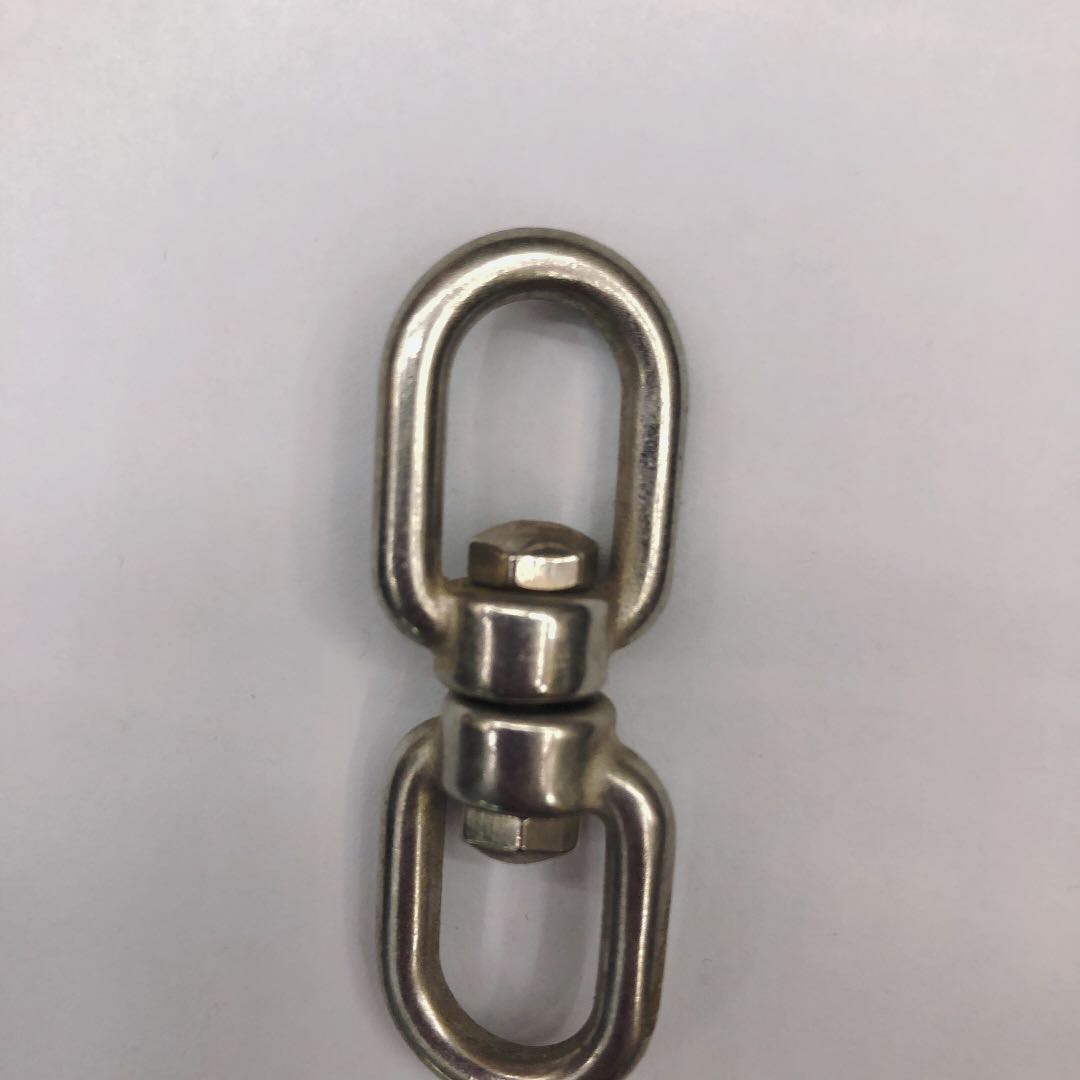

Flexible full-angle movement

Demonstrate the ability of the product to perform 360-degree rotation smoothly and without dead angles. Introduce the internal precision machining process and lubrication treatment measures to ensure smooth action even under frequent operation. Emphasize that this flexibility is essential for tasks that require precise positioning. Engineers used advanced CNC machine tool cutting technology and ultra-fine grinding process to polish each key part, coupled with special grease to fill the gap to reduce friction resistance, and finally realized that no matter which direction of torsion, Caton stagnation will not occur. This is very useful for angle adjustment where precise position control is required, such as a photographic pan/tilt or a medical instrument holder.

Easy and efficient installation experience

Focus on the great convenience of the built-in M8 quick connect device. Demonstrate the entire assembly process in an illustrated manner, including how to quickly dock the interface parts without worrying about the risk of loosening. In addition, supporting tools and service support are also mentioned to make users worry-free. It only takes a few simple steps to complete the firm and reliable assembly-first insert the screw into the pre-punched hole and tighten it until the base completely fits the plane; Then insert the threaded end into the corresponding accessories and gently twist it until you hear a "click" sound to confirm that it is in place. If you encounter any questions, you can also contact the professional customer service team at any time to obtain instant guidance to answer your doubts, so as to ensure that every user can install and use it smoothly.

Wide application prospects in many fields

Overview This product is not limited to a single use in a specific industry, but covers the potential market value of many fields such as mechanical manufacturing, construction engineering and even home DIY. Several typical examples are given to illustrate its versatility, look forward to the future development trend, and predict the possibility of more innovative applications. In addition to the professional-grade equipment mentioned earlier, in fact, many small projects in daily life will also use such a small but fully functional small parts. For example, repairing bicycle chains, decorative lamp hangers or building simple desk arms can play an important role. With the increasing demand for personalized customization, it is expected that such versatile and cost-effective hardware will become more and more popular.

The user story behind the choice of trust

Collect success stories and positive reviews from customers from different backgrounds, describe the problems they encountered before choosing this product and the benefits they received afterwards. Through the real feedback voice to convey trust, encourage other people with similar needs to try to buy, witness the power of quality. "In the past, the machines in our factory often broke down frequently because ordinary iron products were easy to rust," recalled a manufacturing boss. "Since you switched to your company's stainless steel universal rotating ring, the situation has obviously improved many times. The maintenance interval has been greatly extended!" Another outdoor adventure enthusiast said, "With this thing, you're no longer afraid of moisture in the wild! And it's easy to carry, light and easy to carry." It is these real praise has become the driving force for the enterprise to move forward.