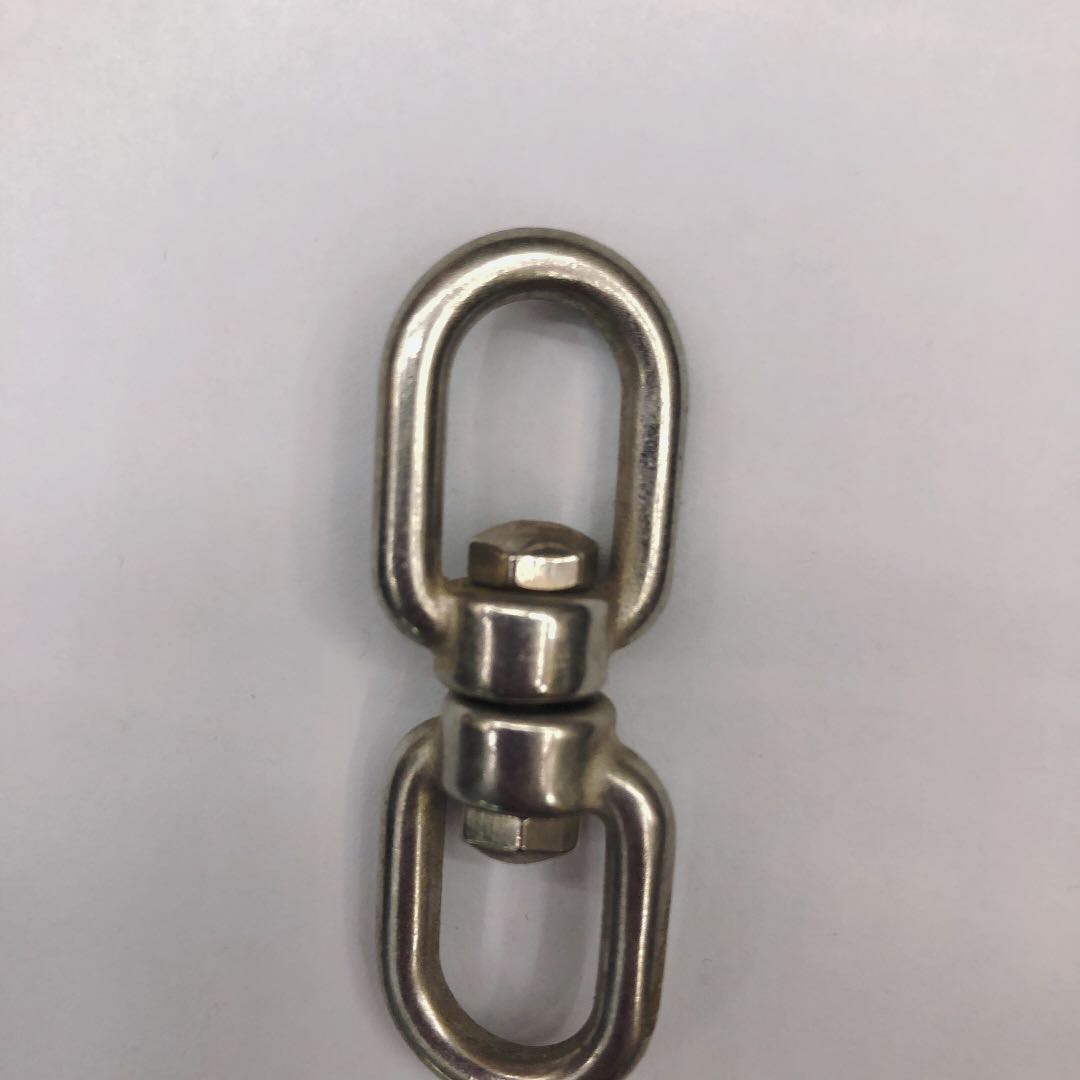

Seiko-forged for harsh environments.

New choice for industrial connection | Comprehensive analysis of 304 stainless steel universal rotating ring

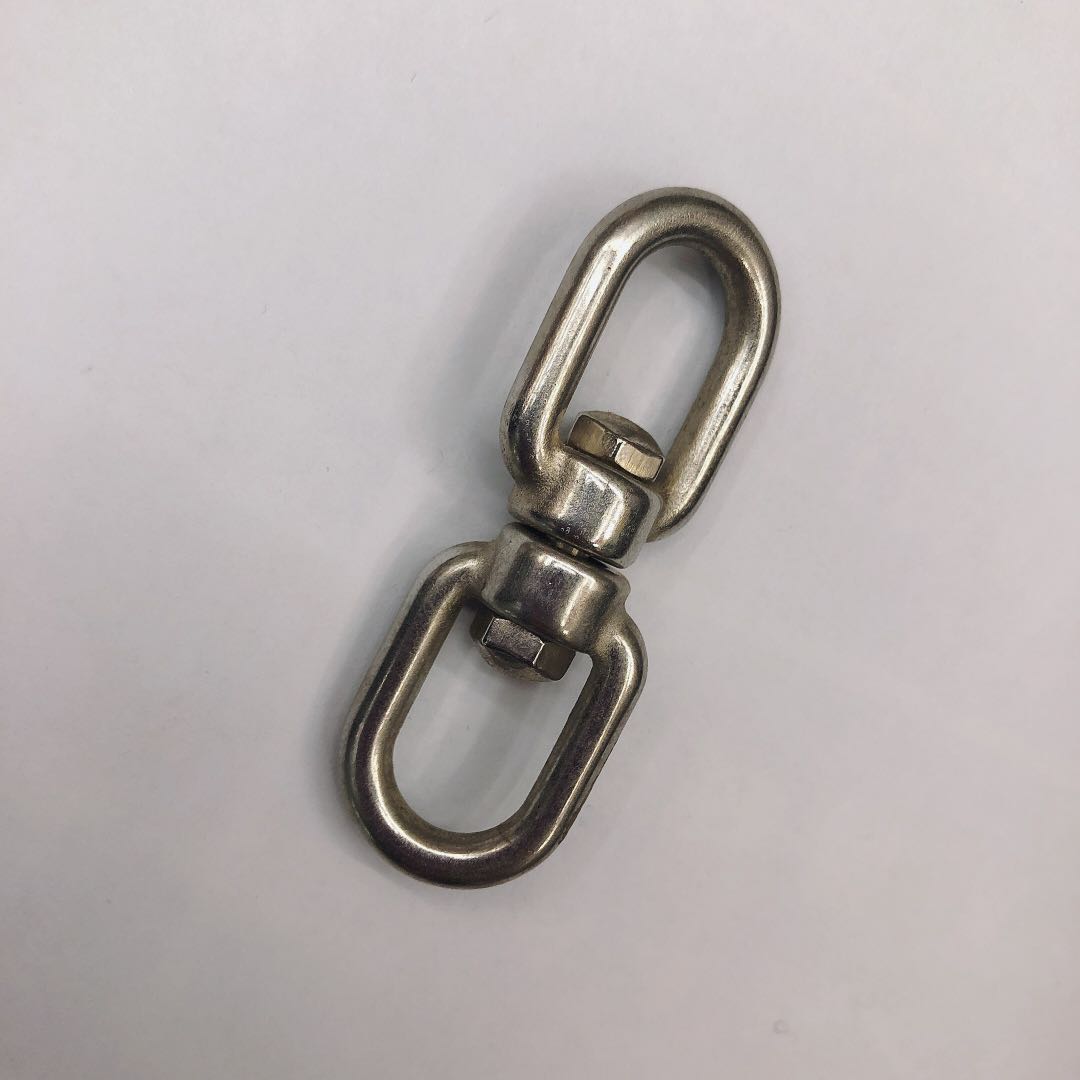

In the face of increasingly complex engineering challenges, traditional fasteners are no longer up to the needs of modern manufacturing. This 304 stainless steel universal rotating ring with its precision machining and flexible steering design, successfully breaking the shackles of regular, is widely used in many industries. Whether it is heavy machinery or light equipment, you can get an efficient and reliable support experience.

The core of this product is the perfect integration of rigid structure and flexible motion, which not only has excellent carrying capacity, but also can maintain stable operation under dynamic conditions, thus greatly extending the life cycle of the whole system.

The power of materials | Why choose 304 stainless steel for high quality joints?

Among the many metals, 304 stainless steel stands out because of its superior oxidation resistance and resistance to acid and alkali attack, especially suitable for working conditions exposed to humid, high temperature or dusty environments. Even under the influence of extreme weather for a long time, it is not easy to deform or wear.

In addition, this alloy also has good welding performance and hot and cold forming characteristics, so that the finished product can achieve higher production consistency without sacrificing accuracy, which is the ideal standard pursued by many high-end engineering projects.

the secret of flexible rotation | how can 360-degree rotation without dead angle improve operation efficiency?

This revolutionary universal design breaks the limitation of single direction fixation, allowing components to swing freely in all directions without stress concentration problems. This is a boon for tasks that require frequent angle adjustments.

Whether it is in the positioning and calibration link on the automated production line or in the angle correction process of the temporary support on the construction site, it can significantly reduce the time waste caused by restrictions and make the whole process smoother and more comfortable.

standardized adaptation of M8 thread | what is the first choice for engineering?

The M8 specification has long become one of the common screw aperture standards worldwide, which means that almost any device involving this type of interface can be seamlessly connected to this series of products, greatly reducing the difficulty of later maintenance for users.

More importantly, the unified standard also means that spare parts are more convenient to obtain. Once there are signs of damage or aging, they can be quickly replaced and updated, thus fundamentally eliminating the economic losses caused by shutdown.

application scenario introduction | multiple actual combat cases from mechanical assembly to outdoor construction

For example, in the assembly line of the automobile industry, engineers use this system to realize the rapid docking between the conveyor belt and other auxiliary tools; and in the field of construction engineering, they can often be seen in the scaffolding connection part to act as a load-bearing shaft role.

Not only that, even some special industries, such as the aviation model development team, will apply it to the UAV PTZ control module to achieve more accurate attitude adjustment effect-these vivid examples are constantly proving its unlimited potential.

Quality verification time | Real test data tells you its durability limit

the data obtained after strict laboratory simulation experiments show that the original form can be maintained intact even under continuous tensile impact of up to hundreds of kilograms. At the same time, there is no obvious oxidation trace on the surface after continuous exposure to the salt spray box for up to 1,000 hours.

Such a strong performance comes from the attitude of striving for perfection in every detail and the result of the escort of the quality inspection system, so that every user is full of confidence in its quality.

Selection Guide | How to match the most suitable model for your project?

Although the basic parameters have been excellent, we still recommend that customers make appropriate screening according to the actual situation of their specific projects. For example, if there are a large number of vibration factors in your working environment, priority should be given to the safety version with locking function. If the main focus is on weight and load considerations, you may as well upgrade and select larger diameter products to further strengthen the stability.

as long as you know the specific index range you need, you can easily find the most suitable configuration scheme to help you successfully complete various tasks and objectives.